2004 chevy tahoe brake line diagram – Delve into the intricacies of your 2004 Chevy Tahoe’s braking system with our comprehensive brake line diagram. From understanding the system’s components to troubleshooting common issues, this guide empowers you to maintain optimal braking performance.

Explore the detailed specifications of your 2004 Chevy Tahoe, including engine capabilities, trim levels, and key features that impact its braking system.

Vehicle Specifications

The 2004 Chevy Tahoe is a full-size SUV known for its ruggedness, versatility, and spacious interior.

It was available in several trim levels, including the base LS, mid-level LT, and luxurious LTZ. All models came standard with rear-wheel drive, while four-wheel drive was optional.

Engine Specifications

The 2004 Tahoe offered two engine options:

- 5.3-liter V8 producing 295 horsepower and 335 lb-ft of torque

- 6.0-liter V8 producing 320 horsepower and 360 lb-ft of torque

Trim Levels

The 2004 Tahoe was available in three trim levels:

- LS:The base trim offered features like air conditioning, power windows, and a CD player.

- LT:The mid-level trim added leather seats, heated mirrors, and a sunroof.

- LTZ:The top-of-the-line trim included navigation, a Bose audio system, and heated and cooled seats.

Features

The 2004 Tahoe offered a range of features to enhance comfort, convenience, and safety, including:

- Third-row seating for up to nine passengers

- Spacious cargo area

- Towing capacity of up to 8,600 pounds

- StabiliTrak electronic stability control

- OnStar emergency communication system

Brake System Overview: 2004 Chevy Tahoe Brake Line Diagram

The 2004 Chevy Tahoe’s braking system is a complex network of components working together to slow or stop the vehicle. The system includes brake pads, rotors, calipers, brake lines, master cylinder, and a brake booster. Each component plays a crucial role in the overall function of the brake system.

Brake Pads

Brake pads are the friction material that makes contact with the brake rotors to slow or stop the vehicle. They are typically made of a semi-metallic or ceramic material and are designed to withstand high temperatures and wear.

Brake Rotors

Brake rotors are the metal discs that the brake pads press against to create friction. They are typically made of cast iron and are designed to dissipate heat quickly.

Calipers

Calipers are the hydraulic devices that squeeze the brake pads against the brake rotors. They are mounted on the wheel hub and are activated by hydraulic pressure from the master cylinder.

Brake Lines

Brake lines are the metal tubes that carry brake fluid from the master cylinder to the calipers. They are typically made of steel or copper and are designed to withstand high pressure.

If you’re looking to minimize recoil on your firearm, consider a best muzzle brake for recoil reduction . These devices redirect propellant gases to counteract recoil and improve accuracy. On the other hand, if you’re upgrading your braking system, don’t overlook the importance of using a durable and corrosion-resistant 3 16 stainless steel brake line . Its superior strength and resistance to rust will ensure reliable performance and longevity.

Master Cylinder

The master cylinder is the heart of the brake system. It is a hydraulic device that converts the force applied to the brake pedal into hydraulic pressure. This pressure is then transmitted to the calipers through the brake lines.

Brake Booster

The brake booster is a vacuum-powered device that assists the driver in applying pressure to the brake pedal. It is located between the brake pedal and the master cylinder.

If you’re looking to minimize recoil on your firearm, a muzzle brake is a great option. These devices work by directing the expanding gases from the cartridge away from the shooter, resulting in reduced felt recoil. When selecting a muzzle brake, it’s important to consider the caliber and application of your firearm.

For example, a 3 16 stainless steel brake line is a popular choice for high-powered rifles due to its durability and corrosion resistance.

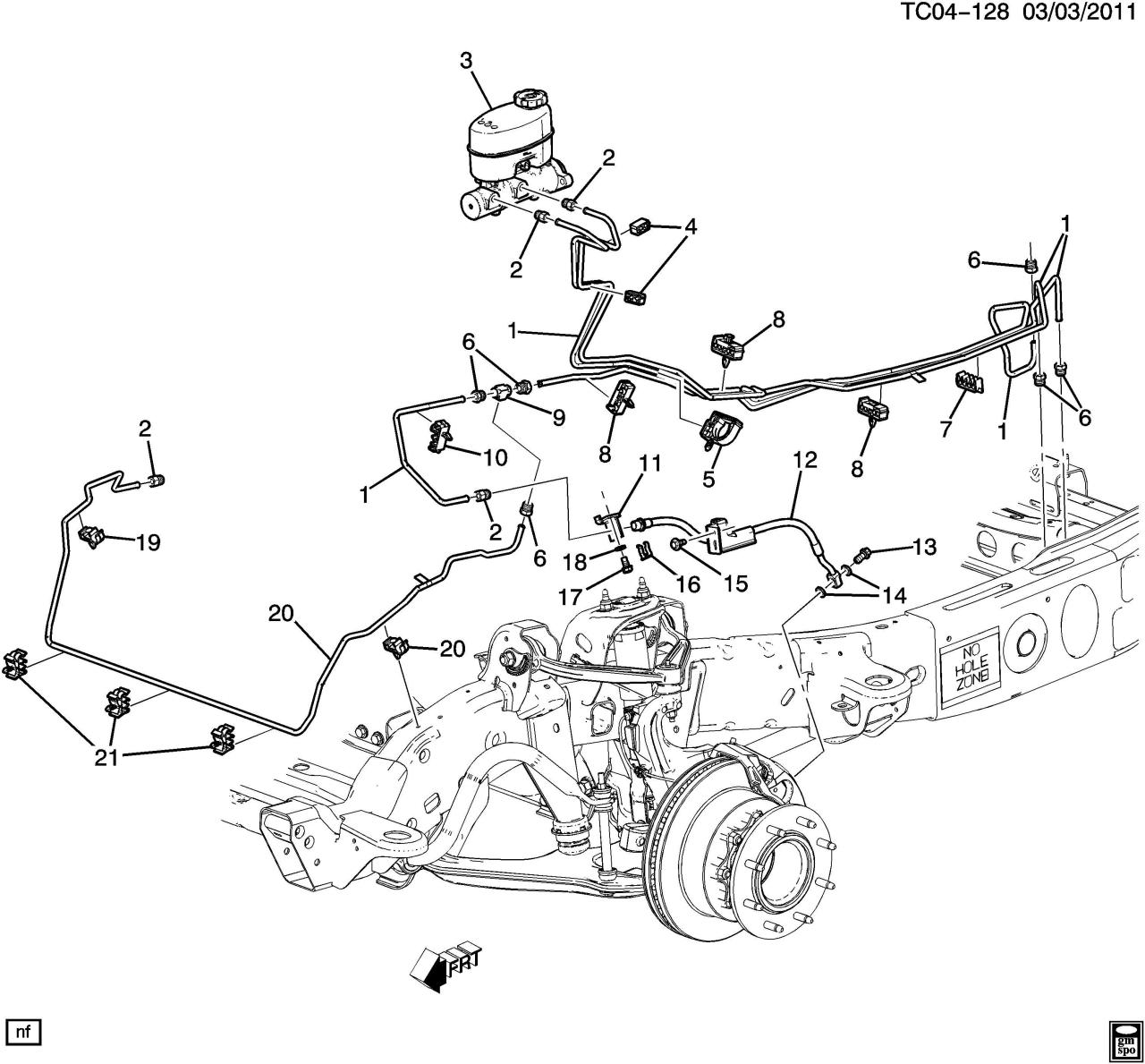

Brake Line Diagram

The brake line diagram provides a visual representation of the brake system’s components and their connections.

The diagram is organized using an HTML table, with clear labels for each component.

Legend

- MC: Master Cylinder

- ABS: Anti-lock Braking System

- PB: Proportioning Block

- FR: Front Right Brake Line

- FL: Front Left Brake Line

- RR: Rear Right Brake Line

- RL: Rear Left Brake Line

| Component | Connection |

|---|---|

| MC | ABS |

| ABS | PB |

| PB | FR |

| PB | FL |

| PB | RR |

| PB | RL |

Brake Line Routing

The brake lines carry brake fluid from the master cylinder to the brake calipers and wheel cylinders at each wheel. They are made of steel tubing and are routed throughout the vehicle in a way that minimizes the risk of damage or leaks.

The brake lines start at the master cylinder, which is located in the engine compartment. From the master cylinder, the lines run to the brake proportioning valve, which is located on the frame rail. The proportioning valve divides the brake fluid pressure between the front and rear brakes.

From the proportioning valve, the brake lines run to the front and rear brake calipers and wheel cylinders. The front brake lines run along the frame rails and then to the front calipers. The rear brake lines run along the axle and then to the rear calipers or wheel cylinders.

Potential Areas for Leaks or Damage

The brake lines are most likely to leak or become damaged at the following locations:

- Where they are connected to the master cylinder, proportioning valve, or brake calipers/wheel cylinders

- Where they run along the frame rails or axle

- Where they are exposed to road debris or other hazards

Brake Line Maintenance

Maintaining your brake lines is crucial for ensuring the safety and performance of your vehicle. Brake lines are responsible for transmitting hydraulic pressure from the master cylinder to the brake calipers and wheel cylinders, which in turn actuate the brake pads or shoes to stop the vehicle.

Regular maintenance helps prevent leaks, corrosion, and other issues that can compromise the integrity of the brake system.

Signs and Symptoms of Brake Line Issues

Several signs and symptoms may indicate potential brake line issues:

Leaking brake fluid

Visible leaks or puddles of brake fluid under the vehicle can indicate a rupture or damage to the brake lines.

Spongy or soft brake pedal

A brake pedal that feels spongy or goes to the floor when pressed can indicate air in the brake lines or a leak.

Reduced braking performance

If the vehicle takes longer to stop or requires more effort to apply the brakes, it could be a sign of a leak or blockage in the brake lines.

ABS warning light

If the Anti-lock Braking System (ABS) warning light illuminates on the dashboard, it could indicate a problem with the brake lines or other components of the ABS system.

Corrosion or rust

Visible corrosion or rust on the brake lines can weaken them and increase the risk of failure.

Inspecting and Replacing Brake Lines

Inspecting and replacing brake lines is a critical part of brake maintenance. Here’s how to do it:

Visual inspection

Regularly inspect the brake lines for any signs of damage, corrosion, or leaks. Look for cracks, bulges, or rust spots.

Pressure test

A pressure test can help identify leaks or blockages in the brake lines. A mechanic will connect a pressure gauge to the brake system and apply pressure to the lines.

Replacement

If the brake lines are damaged or leaking, they must be replaced. Use only high-quality brake lines that meet the specifications for your vehicle. The replacement process typically involves disconnecting the old brake lines, installing the new lines, and bleeding the brake system to remove any air.Regular

brake line maintenance is essential for the safety and reliability of your vehicle. By inspecting and replacing the brake lines as needed, you can help ensure that your brakes perform optimally and keep you and your passengers safe on the road.

Troubleshooting Brake Line Problems

Brake line issues can manifest in various ways, affecting your vehicle’s braking performance. Identifying and resolving these problems promptly is crucial for maintaining safe driving conditions.

Common brake line problems include leaks, corrosion, and damage. Leaks can occur at connections or along the line itself, leading to a loss of brake fluid and reduced braking power. Corrosion weakens the line’s structure, making it more susceptible to failure.

Damage can result from external impacts, such as road debris or accidents.

Diagnosing Brake Line Issues, 2004 chevy tahoe brake line diagram

To troubleshoot brake line problems, follow these steps:

- Check for Leaks:Inspect the brake lines visually for any signs of fluid leaks. Look for wet spots or drips around connections, fittings, and along the line.

- Examine for Corrosion:Inspect the lines for rust or corrosion. Pay attention to areas near the engine, exhaust system, and undercarriage, where moisture and heat can accelerate corrosion.

- Check for Damage:Look for any visible damage to the brake lines, such as kinks, cuts, or punctures. These can occur from road debris, collisions, or improper installation.

- Test Brake Pressure:Use a brake pressure gauge to measure the pressure in the brake system. Low pressure may indicate a leak or blockage in the line.

Tips for Troubleshooting Specific Brake Line Components

- Master Cylinder:Check the master cylinder for leaks or damage. A faulty master cylinder can cause low brake pressure and reduced braking performance.

- Brake Lines:Inspect the brake lines for leaks, corrosion, or damage. Replace any damaged or excessively corroded lines.

- Brake Hoses:Check the brake hoses for leaks or cracks. Replace any damaged or worn hoses.

- Wheel Cylinders:Check the wheel cylinders for leaks or damage. Replace any faulty wheel cylinders.

- Calipers:Inspect the calipers for leaks or damage. Replace any damaged calipers.

Final Conclusion

Mastering your 2004 Chevy Tahoe’s brake line maintenance and troubleshooting empowers you to ensure the safety and reliability of your vehicle. With our comprehensive guide, you’ll navigate brake line issues with confidence, ensuring a smooth and responsive braking experience.

Common Queries

Where can I find the brake line diagram for my 2004 Chevy Tahoe?

Refer to our comprehensive brake line diagram within this guide, which provides a detailed visual representation of the system’s components and their connections.

How often should I inspect my brake lines?

Regular brake line inspections are crucial for safety. We recommend scheduling inspections every 12,000 miles or annually, whichever comes first.

What are the common signs of brake line problems?

Keep an eye out for warning signs like spongy or soft brake pedals, unusual noises during braking, and visible leaks or corrosion on the brake lines.