Delve into the world of 3/16 stainless steel brake lines, where durability, corrosion resistance, and superior performance intertwine. This comprehensive guide unravels the intricacies of these essential automotive components, providing a roadmap for informed decision-making and enhanced braking experiences.

From the intricacies of material composition to the practicalities of installation and maintenance, this discourse delves into every facet of 3/16 stainless steel brake lines, empowering you with the knowledge to make informed choices for your vehicle’s braking system.

Material Composition

3/16 stainless steel brake line is composed primarily of iron, chromium, and nickel. The exact composition varies depending on the grade of stainless steel used, but typically it contains around 70% iron, 18% chromium, and 8% nickel.

The chromium content gives stainless steel its corrosion resistance, while the nickel content increases its strength and ductility. Stainless steel is also harder than other types of steel, making it more resistant to wear and tear.

Comparison to Other Brake Lines

Compared to other types of brake lines, such as copper or rubber, stainless steel brake line offers several advantages:

- Corrosion resistance:Stainless steel is highly resistant to corrosion, making it ideal for use in harsh environments.

- Strength:Stainless steel is stronger than copper or rubber, making it less likely to fail under pressure.

- Durability:Stainless steel is a durable material that can withstand years of use without losing its performance.

Applications

3/16 stainless steel brake line finds applications in a wide range of industries, particularly in automotive and industrial settings, due to its exceptional durability, corrosion resistance, and ability to withstand high pressure.

In automotive applications, it is commonly used in brake systems, including brake lines, brake hoses, and brake calipers, where it ensures the reliable transfer of brake fluid from the master cylinder to the wheel cylinders or calipers, facilitating effective braking.

Automotive Applications

- Brake lines: Conveying brake fluid from the master cylinder to the wheel cylinders or calipers.

- Brake hoses: Connecting rigid brake lines to movable components like calipers and wheel cylinders, allowing for flexibility and preventing damage due to movement.

- Brake calipers: Stainless steel brake lines are used in brake calipers to connect the caliper to the master cylinder and transmit brake fluid, enabling the caliper to engage with the brake pads and stop the vehicle.

In industrial applications, 3/16 stainless steel brake line is utilized in hydraulic systems, fluid transfer lines, and high-pressure applications, where it provides a robust and reliable solution for conveying fluids and gases.

Industrial Applications

- Hydraulic systems: 3/16 stainless steel brake line serves as a conduit for hydraulic fluid in industrial machinery, enabling the transmission of power and control.

- Fluid transfer lines: It is employed in various industrial processes to transport fluids, such as oils, chemicals, and gases, ensuring safe and efficient fluid transfer.

- High-pressure applications: In industries like oil and gas, stainless steel brake line is used for high-pressure fluid transfer, withstanding extreme pressures and ensuring system integrity.

Installation

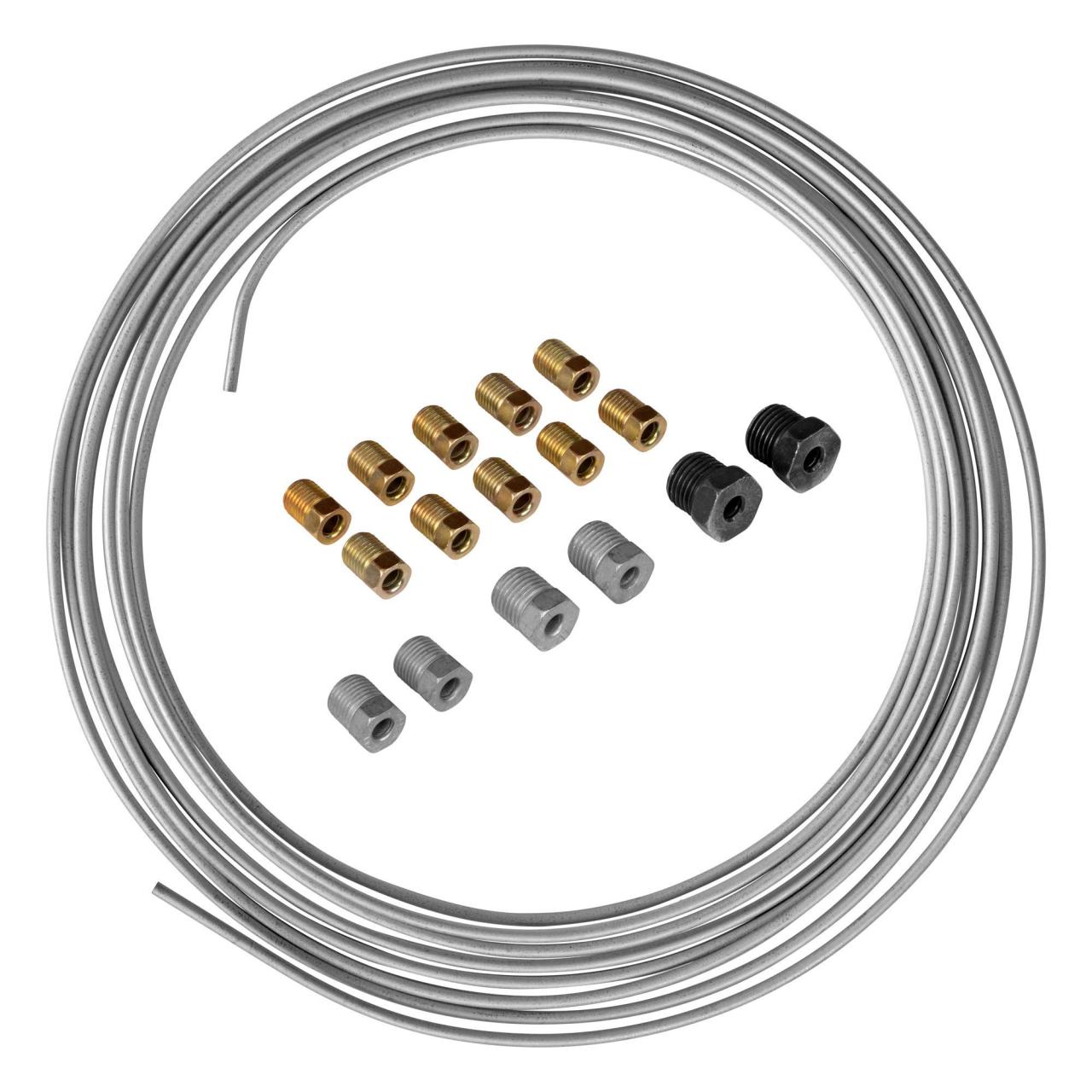

Installing 3/16 stainless steel brake lines is a relatively straightforward process that can be completed with basic tools and materials. By following the steps Artikeld below, you can ensure a successful installation that will provide improved braking performance and reliability.

Tools and Materials

- 3/16 stainless steel brake line

- Brake line bender

- Double flaring tool

- Brake fluid

- Wrenches

- Safety glasses

Safety Precautions, 3/16 stainless steel brake line

- Wear safety glasses when working with brake lines.

- Brake fluid is toxic, so avoid contact with skin and eyes. If contact occurs, rinse thoroughly with water.

- Do not smoke or use open flames near brake fluid, as it is flammable.

- Jack up the vehicle and secure it with jack stands before starting work on the brake lines.

Installation Steps

- Remove the old brake lines.

- Measure and cut the new stainless steel brake lines to the desired length.

- Use a brake line bender to shape the brake lines as needed.

- Use a double flaring tool to create flares on the ends of the brake lines.

- Install the new brake lines and tighten the fittings securely.

- Bleed the brake system to remove any air from the lines.

Maintenance

Maintaining 3/16 stainless steel brake lines is crucial for ensuring optimal performance and safety. Regular inspections and cleaning are essential to prevent corrosion, leaks, and other issues.

Inspection and Cleaning

Inspect the brake lines regularly for signs of wear, damage, or corrosion. Clean the lines with a mild detergent and water, and remove any debris or dirt that may have accumulated. Pay special attention to areas where the lines are exposed to moisture or road salt.

Corrosion Prevention

To prevent corrosion, apply a protective coating to the brake lines. This coating can be a clear lacquer or a specialized anti-corrosion spray. Regularly inspect the coating and reapply as needed.

Additional Tips

* Use only high-quality brake fluid and replace it according to the manufacturer’s recommendations.

- Avoid overtightening the brake line fittings, as this can damage the threads and lead to leaks.

- If you notice any leaks or damage to the brake lines, have them repaired or replaced immediately.

By following these maintenance tips, you can extend the lifespan of your 3/16 stainless steel brake lines and ensure their optimal performance and safety.

Whether you’re working on your Chevy or looking to upgrade your trailer, having the right parts is crucial. For a secure and reliable braking system, consider a diagram chevy rear drum brake assembly . It provides a comprehensive overview of the components and their assembly, ensuring proper installation and maintenance.

Additionally, if you’re hauling heavy loads, a 3500 lb trailer axle with brakes is an excellent choice. Its sturdy construction and braking capabilities will give you peace of mind on the road.

Troubleshooting

Identifying and resolving common issues with 3/16 stainless steel brake lines ensures optimal performance and safety. Various problems can arise during installation, maintenance, or regular use.

Leaking Brake Lines

- Loose fittings:Inspect and tighten all fittings to ensure a secure connection.

- Damaged brake line:Examine the line for any cracks, cuts, or abrasions. Replace damaged sections immediately.

- Improper installation:Verify that the brake line is properly routed and secured, without any sharp bends or kinks.

Spongy Brake Pedal

- Air in the brake lines:Bleed the brake system to remove trapped air, which can cause a spongy pedal.

- Leaking master cylinder:Inspect the master cylinder for leaks and replace if necessary.

- Worn brake pads:Replace worn brake pads to restore proper braking performance.

Brake Line Vibration

- Loose mounting brackets:Ensure that the brake line mounting brackets are securely tightened.

- Improper routing:Check if the brake line is rubbing against any components, causing vibration.

- Damaged brake line:Inspect the brake line for any physical damage that could lead to vibration.

Design Considerations

The design of 3/16 stainless steel brake lines involves careful consideration of several factors to ensure optimal performance and safety in various applications.

If you’re looking to replace the rear drum brake assembly on your Chevy, check out the diagram for a step-by-step guide. For heavier loads, consider a 3500 lb trailer axle with brakes to ensure a safe and controlled towing experience.

Key factors influencing the design include:

- Pressure: The brake line must withstand the high pressure generated by the braking system.

- Temperature: The brake line must be able to tolerate the heat generated by the braking process.

- Flow rate: The brake line must allow for sufficient flow of brake fluid to activate the brakes effectively.

Specific Applications

Depending on the specific application, additional design considerations may come into play:

- Automotive:Brake lines must be flexible to accommodate vehicle movement and vibration.

- Industrial machinery:Brake lines may require corrosion resistance in harsh environments.

- Aerospace:Brake lines must meet stringent safety and performance standards.

Advantages and Disadvantages

3/16 stainless steel brake lines offer a range of advantages and disadvantages that make them suitable for various applications. Let’s explore the pros and cons in detail.

Cost Comparison

- Compared to other brake line materials like rubber and nickel-copper, stainless steel lines are more expensive initially.

- However, their superior durability and longevity make them a cost-effective choice in the long run, reducing the need for frequent replacements.

Performance and Durability

- Stainless steel brake lines provide excellent braking performance due to their high pressure resistance and minimal expansion.

- They are highly durable, resistant to corrosion, and can withstand extreme temperatures and harsh environments.

- In comparison, rubber brake lines are prone to expansion under pressure, which can affect braking efficiency.

Longevity and Maintenance

- 3/16 stainless steel brake lines have a significantly longer lifespan compared to rubber or nickel-copper lines.

- They require minimal maintenance and do not need to be replaced as frequently as other materials.

- Rubber brake lines, on the other hand, deteriorate over time and may need to be replaced every few years.

Industry Standards and Regulations: 3/16 Stainless Steel Brake Line

The automotive industry has established specific standards and regulations for the production and installation of brake lines, including 3/16 stainless steel brake line. These standards are crucial for ensuring the safety and reliability of braking systems in vehicles.

Adhering to industry standards and regulations is essential for several reasons. Firstly, it helps ensure that brake lines meet minimum performance and safety requirements. Secondly, it promotes consistency in the design and installation of brake lines, reducing the risk of errors or defects.

Thirdly, it facilitates communication and collaboration among manufacturers, engineers, and technicians involved in the automotive industry.

Relevant Standards and Regulations

- SAE J1143: This standard specifies the material requirements, dimensions, and performance testing procedures for hydraulic brake lines and fittings.

- FMVSS 106: This Federal Motor Vehicle Safety Standard establishes minimum performance requirements for brake systems, including the brake lines.

- DOT FMVSS 106: This regulation requires that brake lines meet specific safety and performance standards, including resistance to corrosion, fatigue, and pressure.

- ASME B31.1: This standard provides guidance on the design, fabrication, installation, and inspection of power piping systems, including brake lines.

Ultimate Conclusion

In the realm of automotive safety, 3/16 stainless steel brake lines stand as a testament to innovation and reliability. Their exceptional durability, corrosion resistance, and unwavering performance make them an indispensable choice for those seeking to elevate their braking systems to new heights.

As you embark on your automotive adventures, let the knowledge imparted within this guide serve as your trusted companion, ensuring that your braking system operates with precision and unwavering reliability.

Detailed FAQs

What sets 3/16 stainless steel brake lines apart from other types of brake lines?

3/16 stainless steel brake lines distinguish themselves through their superior durability, corrosion resistance, and ability to withstand extreme temperatures and pressures, ensuring optimal braking performance and longevity.

How do I determine the correct length of 3/16 stainless steel brake line I need?

To ascertain the appropriate length, measure the existing brake line or consult your vehicle’s manufacturer specifications. Ensure that the new brake line is of equal or slightly longer length to accommodate any necessary bends or adjustments.

What are the key advantages of using 3/16 stainless steel brake lines?

3/16 stainless steel brake lines offer a plethora of advantages, including enhanced durability, exceptional corrosion resistance, improved braking response, and reduced maintenance requirements, contributing to a safer and more efficient braking system.