3 8 24 brake line fitting – Step into the world of brake line fittings with our comprehensive guide to 3/8-24 brake line fittings. Dive into the specifications, applications, installation techniques, materials, and maintenance tips that will empower you to tackle any brake line project with confidence.

Whether you’re a seasoned mechanic or a DIY enthusiast, this guide will provide you with the knowledge and insights to ensure your brake system operates at its peak performance.

3/8-24 Brake Line Fitting Specifications

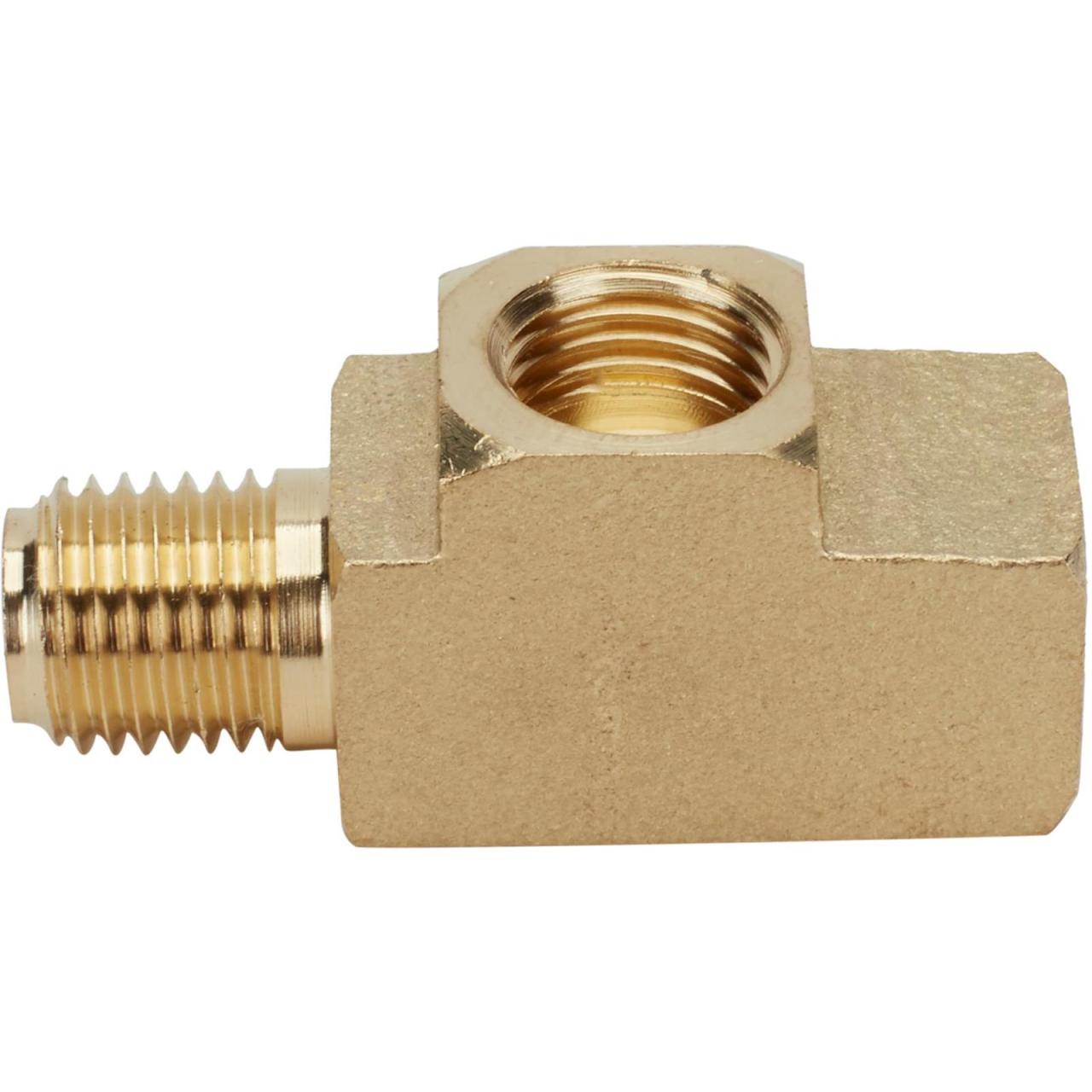

A 3/8-24 brake line fitting is a type of pipe fitting used to connect brake lines in automotive hydraulic brake systems. It has a male thread with a diameter of 3/8 inch and 24 threads per inch.

The following table provides technical details about the 3/8-24 brake line fitting:

| Diameter | 3/8 inch |

|---|---|

| Pitch | 24 threads per inch |

| Thread Type | Inverted flare (SAE J512) |

Compatibility and Applications

3/8-24 brake line fittings are compatible with a wide range of brake line types and sizes, making them a versatile choice for various brake system applications. These fittings are commonly used with steel brake lines, which offer a combination of durability and flexibility.

They are also compatible with stainless steel brake lines, which provide superior corrosion resistance and longevity.

In terms of brake line sizes, 3/8-24 fittings are typically used with brake lines ranging from 3/16 inch to 1/4 inch in diameter. This makes them suitable for use in a variety of brake systems, from small-bore lines found in motorcycles and compact cars to larger-bore lines used in heavy-duty vehicles.

Common Applications

3/8-24 brake line fittings are commonly found in various components of brake systems, including brake calipers, master cylinders, and proportioning valves.

- Brake Calipers:3/8-24 fittings are often used to connect brake lines to brake calipers, which house the brake pads and pistons that apply pressure to the brake rotors.

- Master Cylinders:These fittings are also used to connect brake lines to the master cylinder, which is responsible for generating hydraulic pressure in the brake system when the brake pedal is depressed.

- Proportioning Valves:3/8-24 fittings can be found on proportioning valves, which distribute brake fluid pressure evenly to the front and rear brakes, ensuring balanced braking performance.

Installation and Removal

Installing and removing 3/8-24 brake line fittings requires careful attention to ensure a secure and leak-free connection. The following steps provide a comprehensive guide to both processes:

Installing 3/8-24 Brake Line Fittings

- Gather necessary tools: flare nut wrench, torque wrench, brake fluid, rags, and safety glasses.

- Clean the brake line and fitting surfaces thoroughly to remove any dirt or debris.

- Apply a small amount of brake fluid to the threads of the fitting.

- Tighten the fitting onto the brake line using a flare nut wrench, following the specified torque value.

- Double-check the tightness of the fitting using a torque wrench.

- Bleed the brake system to remove any air from the lines.

Removing 3/8-24 Brake Line Fittings

- Wear safety glasses and gather necessary tools: flare nut wrench, rags, and brake fluid.

- Loosen the fitting using a flare nut wrench.

- Remove the fitting and discard the old sealing washer.

- Clean the brake line and fitting surfaces to remove any debris.

- Install a new sealing washer onto the fitting.

- Tighten the fitting onto the brake line using a flare nut wrench, following the specified torque value.

- Bleed the brake system to remove any air from the lines.

Safety Precautions:

- Always wear safety glasses when working with brake fluid.

- Brake fluid is toxic and should be handled with care. Avoid contact with skin and eyes.

- Do not smoke or eat while working with brake fluid.

- Keep brake fluid away from children and pets.

Materials and Construction

3/8-24 brake line fittings are typically constructed using a variety of materials, each with its own unique set of advantages and disadvantages.

The most common materials used in the construction of these fittings include:

Steel

Steel is a strong and durable material that is resistant to corrosion. However, steel fittings are also relatively heavy and can be difficult to work with.

Towing heavy loads requires a reliable brake controller, and the tow-pro liberty electric brake controller fits the bill perfectly. It’s designed for trailers with electric brakes, and its compact size makes it easy to mount in any vehicle. Paired with a 3 16 stainless steel brake line , you can ensure a secure and long-lasting connection to your trailer’s brakes.

Stainless Steel

Stainless steel is a more corrosion-resistant material than steel, and it is also stronger. However, stainless steel fittings are more expensive than steel fittings.

Aluminum, 3 8 24 brake line fitting

Aluminum is a lightweight and corrosion-resistant material. However, aluminum fittings are not as strong as steel or stainless steel fittings.

For your towing adventures, the tow-pro liberty electric brake controller offers precise and reliable braking. It seamlessly integrates with your vehicle’s electrical system, providing effortless control over your trailer’s brakes. Additionally, consider upgrading your brake system with a durable 3 16 stainless steel brake line . Its corrosion-resistant construction ensures long-lasting performance, enhancing your safety on the road.

Maintenance and Troubleshooting

Regular maintenance and troubleshooting are crucial for ensuring the proper functionality and longevity of 3/8-24 brake line fittings. By following these tips, you can prevent leaks, maintain optimal braking performance, and extend the lifespan of your brake system.

Maintenance Tips

- Inspect fittings regularly:Visually inspect the fittings for any signs of damage, corrosion, or leaks. Tighten any loose fittings promptly.

- Clean fittings:Use a wire brush or compressed air to remove dirt and debris from the fittings. This will prevent contamination and ensure proper sealing.

- Lubricate threads:Apply a small amount of anti-seize compound to the threads of the fittings before installation. This will reduce friction and prevent galling.

- Replace worn fittings:If a fitting is damaged or worn, replace it immediately. Do not attempt to repair damaged fittings, as this could compromise the integrity of the brake system.

Troubleshooting Common Problems

- Leaks:If you notice any leaks from the brake line fittings, first check if the fittings are properly tightened. If tightening does not resolve the leak, inspect the fittings for damage or corrosion. Replace damaged fittings as necessary.

- Loose fittings:If a fitting becomes loose, tighten it promptly. Loose fittings can cause leaks and compromise the braking performance.

- Corrosion:Corrosion can weaken the fittings and lead to leaks. Remove any corrosion using a wire brush or sandpaper, and apply anti-seize compound to the threads before reinstallation.

- Stripped threads:If the threads on a fitting become stripped, you may need to replace the fitting or use a thread repair kit to restore the threads.

Wrap-Up: 3 8 24 Brake Line Fitting

From understanding the compatibility of 3/8-24 brake line fittings to mastering their installation and maintenance, this guide has equipped you with the essential knowledge to keep your brake system running smoothly and safely.

Remember, regular maintenance and proper installation are key to preventing leaks, ensuring optimal braking performance, and extending the lifespan of your brake components.

FAQ Section

What are the key specifications of a 3/8-24 brake line fitting?

A 3/8-24 brake line fitting has a diameter of 3/8 inch and a thread pitch of 24 threads per inch.

What materials are commonly used in the construction of 3/8-24 brake line fittings?

Common materials include steel, stainless steel, and aluminum. Steel is the most affordable option, while stainless steel offers superior corrosion resistance, and aluminum provides a lightweight and durable solution.

What are the common applications of 3/8-24 brake line fittings?

These fittings are commonly used in brake calipers, master cylinders, and proportioning valves.