At the heart of every vehicle’s braking system lies a crucial component—the 3/8-24 brake line fitting. Join us as we delve into the world of this essential part, exploring its functions, types, and the intricacies of its installation and maintenance.

Brace yourself for a journey filled with insights, practical tips, and a touch of storytelling magic.

As we navigate the intricacies of brake line fittings, we’ll uncover the secrets of proper selection, ensuring compatibility with your specific brake line materials. Step-by-step guidance will empower you to tackle installation and removal with confidence, while troubleshooting tips will arm you with the knowledge to address any challenges that may arise.

Product Overview

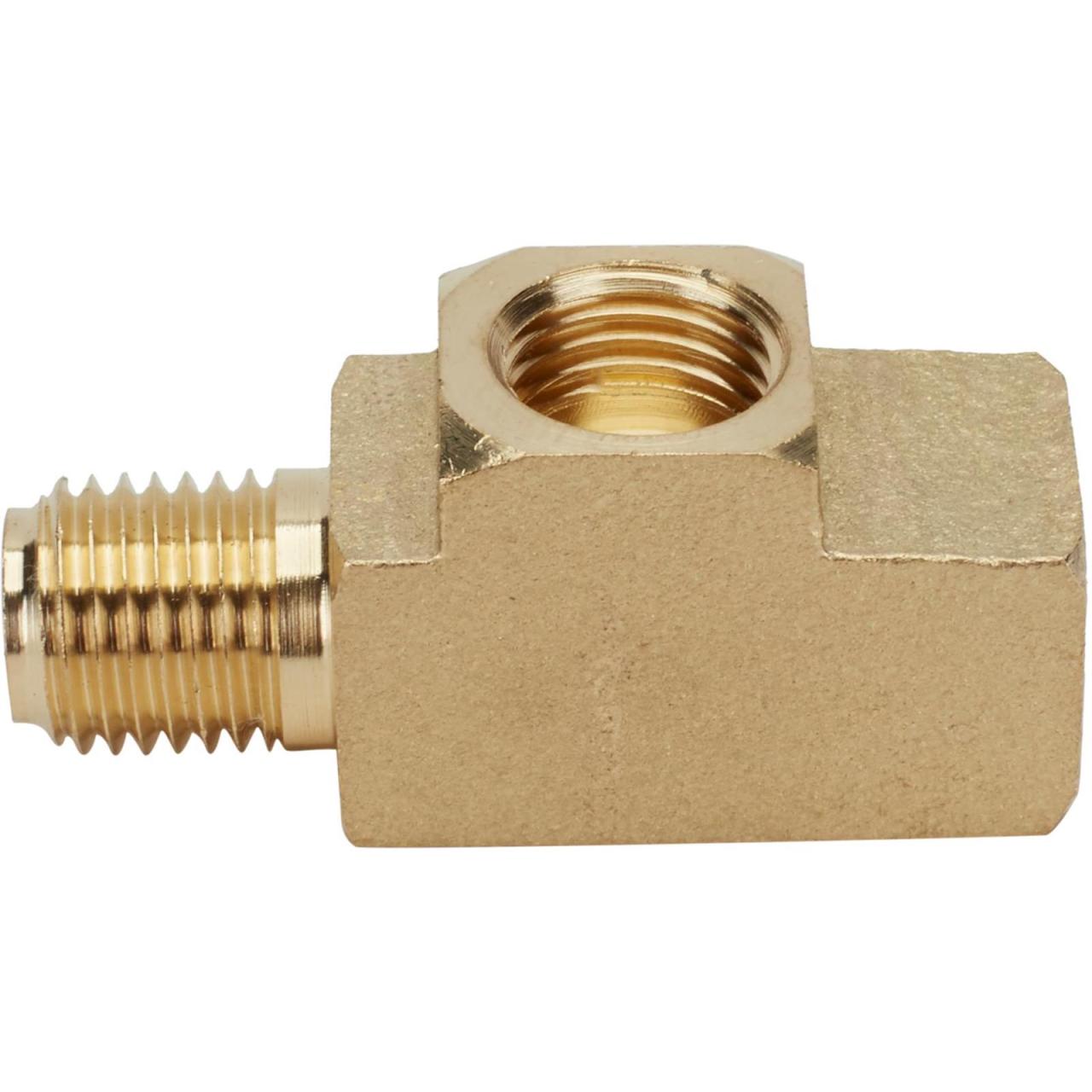

A 3/8-24 brake line fitting is a crucial component in automotive brake systems. It serves as a connector between the brake line and other brake system components, such as calipers, wheel cylinders, and master cylinders.

This fitting is typically made of durable materials like steel or brass and is designed to withstand the high pressure and vibration encountered in brake systems. It features a 3/8-inch diameter and a 24-thread-per-inch (TPI) pitch, which ensures a secure and leak-proof connection.

Dimensions and Specifications

- Diameter: 3/8 inch

- Thread Pitch: 24 TPI

- Material: Typically steel or brass

- Pressure Rating: Varies depending on material and application

Applications

- Connecting brake lines to calipers

- Connecting brake lines to wheel cylinders

- Connecting brake lines to master cylinders

- Used in various automotive brake systems, including hydraulic and air brake systems

Types and Compatibility

3/8-24 brake line fittings come in various types to suit different brake line configurations and materials. Understanding these types and their compatibility is crucial for ensuring a secure and leak-free brake system.

Fitting Types

- Male Fittings:These fittings have external threads and are designed to connect to female fittings or brake line components with internal threads.

- Female Fittings:These fittings have internal threads and are intended to connect to male fittings or brake line components with external threads.

- Straight Fittings:These fittings are used to connect brake lines in a straight line, without changing the direction of the line.

- Angled Fittings:These fittings are designed to change the direction of the brake line, available in various angles such as 45 or 90 degrees.

Compatibility with Brake Line Materials, 3/8-24 brake line fitting

3/8-24 brake line fittings are compatible with various brake line materials, including:

- Copper:Copper brake lines are commonly used in older vehicles and are compatible with 3/8-24 brake line fittings.

- Steel:Steel brake lines are durable and resistant to corrosion, making them suitable for use with 3/8-24 brake line fittings.

- Stainless Steel:Stainless steel brake lines are highly corrosion-resistant and long-lasting, and they can be used with 3/8-24 brake line fittings.

Importance of Proper Fitting Selection

Selecting the correct 3/8-24 brake line fitting is crucial to ensure proper brake line installation and functionality. Fittings should match the brake line size and thread pitch. Using incorrect fittings can lead to leaks, reduced braking performance, and even brake failure.

Installation and Removal

Installing and removing a 3/8-24 brake line fitting requires attention to detail and the use of appropriate tools. This guide provides step-by-step instructions and safety precautions to ensure a secure and leak-free connection.

Installing a 3/8-24 Brake Line Fitting

- Gather necessary tools: flare nut wrench, torque wrench, brake cleaner, thread sealant.

- Clean the brake line and fitting threads with brake cleaner.

- Apply thread sealant to the male threads of the fitting.

- Hand-tighten the fitting onto the brake line.

- Use a torque wrench to tighten the fitting to the specified torque (typically 11-15 ft-lbs).

Removing a 3/8-24 Brake Line Fitting

- Loosen the fitting using a flare nut wrench.

- Remove the fitting by hand.

- Clean the threads of the brake line and fitting.

- Inspect the fitting for damage and replace if necessary.

Safety Precautions

Always wear safety glasses and gloves when working with brake lines.

Use only the specified torque for tightening the fitting.

Leak test the connection after installation to ensure a secure seal.

Maintenance and Troubleshooting

Regular maintenance is crucial to ensure the proper functioning of 3/8-24 brake line fittings. This involves regular inspections for leaks, corrosion, or damage. Preventive measures like lubrication and cleaning can extend their lifespan. Timely replacements are also essential to maintain optimal performance and safety.

Common Maintenance Procedures

- Inspect fittings regularly:Check for leaks, corrosion, or damage. Tighten any loose fittings promptly.

- Lubricate fittings:Apply a small amount of brake fluid or anti-seize compound to prevent corrosion and ease installation/removal.

- Clean fittings:Use a wire brush or compressed air to remove dirt and debris.

Potential Issues and Troubleshooting

- Leaks:Tighten fittings, replace O-rings, or use a leak sealant.

- Corrosion:Clean fittings, apply anti-corrosion spray, or replace severely corroded fittings.

- Stripped threads:Use a thread repair kit or replace the fitting.

Importance of Regular Inspections and Replacements

Regular inspections and timely replacements are vital for safety. Worn or damaged fittings can compromise the integrity of the brake system, potentially leading to accidents. Inspections allow for early detection of issues, while replacements ensure the system’s reliability and performance.

Safety Considerations

When working with brake line fittings, safety should be your top priority. These fittings are critical components in your vehicle’s braking system, and improper installation or maintenance can lead to serious consequences.

It’s essential to use high-quality fittings that meet industry standards. Cheap or poorly made fittings may fail prematurely, leading to brake failure and potential accidents. Always follow the manufacturer’s instructions carefully during installation to ensure a secure and leak-free connection.

Potential Consequences of Improper Installation or Maintenance

- Brake failure: Improperly installed or maintained fittings can leak brake fluid, leading to reduced braking performance or complete brake failure.

- Vehicle damage: Leaking brake fluid can damage other components in your vehicle, such as the brake pads, rotors, and calipers.

- Personal injury: A sudden loss of braking power can lead to accidents, potentially causing serious injuries or fatalities.

Safety Tips and Warnings

- Always use high-quality fittings that meet industry standards.

- Follow the manufacturer’s instructions carefully during installation.

- Inspect your brake line fittings regularly for leaks or damage.

- Have your brake system inspected and serviced by a qualified mechanic at least once a year.

- Never attempt to repair or replace brake line fittings yourself unless you have the proper training and experience.

Industry Standards and Regulations

The 3/8-24 brake line fittings adhere to stringent industry standards and regulations to ensure safety and reliability in automotive brake systems.

Maintaining your truck’s braking system is essential for safety. The brake tech tools original truck inspector is an indispensable tool for diagnosing and repairing brake issues. This comprehensive kit includes everything you need to keep your truck’s brakes in top condition.

Compliance with these standards is crucial for manufacturers and users to guarantee the integrity and performance of brake line connections.

Relevant Standards

- SAE J533:Specifies the dimensions, materials, and performance requirements for 3/8-24 brake line fittings.

- DOT FMVSS 106:Federal Motor Vehicle Safety Standard governing brake system components, including brake line fittings.

- ISO 4038:International standard for brake line fittings, including 3/8-24 size.

Importance of Compliance

Compliance with industry standards ensures:

- Interchangeability:Fittings meet standardized dimensions, allowing for easy replacement and compatibility with different brake systems.

- Safety:Fittings are designed to withstand the high pressures and vibrations encountered in brake systems, preventing leaks and failures.

- Reliability:Standardized materials and manufacturing processes ensure consistent performance and durability.

Regulatory Bodies

Regulatory bodies enforce industry standards and ensure compliance:

- SAE International:Develops and publishes automotive standards, including those for brake line fittings.

- National Highway Traffic Safety Administration (NHTSA):Enforces FMVSS 106, ensuring compliance with brake system safety regulations.

- International Organization for Standardization (ISO):Establishes international standards for various industries, including automotive.

Related Products and Accessories

3/8-24 brake line fittings often work in conjunction with other components to ensure a complete and functional brake system. These related products and accessories play crucial roles in enhancing performance, safety, and ease of installation.

Using compatible components is paramount for optimal performance and safety. Mismatched or incompatible parts can compromise the integrity of the brake system, leading to potential leaks, reduced braking efficiency, or even system failure.

Brake Lines

Brake lines are essential for transmitting hydraulic pressure from the master cylinder to the brake calipers or wheel cylinders. They are typically made of flexible rubber or rigid metal and must be compatible with the specific brake line fittings being used.

When it comes to go karts, safety is paramount. That’s why it’s crucial to invest in high-quality brake pads. Check out brake pads for a go kart to find the perfect set for your needs. Remember, proper maintenance and inspection are key to ensuring a smooth and safe ride.

Brake Fittings

Brake fittings are used to connect brake lines to other components, such as calipers, master cylinders, or proportioning valves. They come in various sizes and configurations to accommodate different brake line diameters and mounting requirements.

Brake Fluid

Brake fluid is a hydraulic fluid that transmits pressure within the brake system. It must be compatible with the type of brake line fittings and brake lines being used.

Bleeder Screws

Bleeder screws are used to remove air from the brake system during bleeding. They are typically located on the calipers or wheel cylinders and must be compatible with the specific brake line fittings being used.

Brake Line Wrenches

Brake line wrenches are specialized tools designed to tighten and loosen brake line fittings. They come in various sizes and shapes to accommodate different fitting configurations.

For a smooth and safe ride on your go-kart, it’s crucial to have reliable brake pads. Check out brake pads for a go kart to find the perfect fit for your vehicle. These pads are designed to provide exceptional stopping power while minimizing wear and tear on your brake system.

Additional Information

In addition to the topics covered above, here are some additional information that may be useful to readers.

The 3/8-24 brake line fitting is a common fitting used in brake systems. It is typically used to connect brake lines to brake calipers and wheel cylinders.

Historical Development

- The 3/8-24 brake line fitting was first developed in the early 1900s.

- It was originally used on hydraulic brake systems.

- The 3/8-24 brake line fitting is still widely used today on both hydraulic and air brake systems.

Industry Trends

- The use of 3/8-24 brake line fittings is increasing as more and more vehicles are equipped with hydraulic brake systems.

- The development of new materials and technologies is also leading to the development of new and improved 3/8-24 brake line fittings.

Best Practices

- When installing a 3/8-24 brake line fitting, it is important to use a torque wrench to tighten the fitting to the proper torque.

- It is also important to use a thread sealant on the threads of the fitting to prevent leaks.

- Regularly inspecting brake line fittings for leaks is important to ensure the proper functioning of the brake system.

Ultimate Conclusion: 3/8-24 Brake Line Fitting

In the realm of automotive safety, the 3/8-24 brake line fitting plays an indispensable role. By understanding its intricacies, you gain the power to maintain a reliable and responsive braking system. Remember, attention to detail and adherence to industry standards are paramount.

As you embrace the knowledge shared within this guide, you’ll be well-equipped to ensure the smooth and safe operation of your vehicle.

Common Queries

What is the purpose of a 3/8-24 brake line fitting?

A 3/8-24 brake line fitting is a crucial component that connects brake lines, allowing fluid to flow between them. It ensures a secure and leak-free connection, vital for the proper functioning of your vehicle’s braking system.

How do I choose the right 3/8-24 brake line fitting for my vehicle?

Selecting the correct fitting is essential for compatibility with your brake line material and size. Consult your vehicle’s specifications or seek guidance from a qualified mechanic to determine the appropriate fitting for your specific application.

What are the common issues associated with 3/8-24 brake line fittings?

Leaks, corrosion, and improper installation are common issues. Regular inspections and maintenance, including proper torque specifications and leak testing, can help prevent these problems and ensure the longevity of your brake line fittings.