Embark on an in-depth exploration of 30 30 brake chamber short stroke, a braking system component that plays a pivotal role in ensuring vehicle safety and performance. Delve into its specifications, applications, and the advantages it offers, gaining a comprehensive understanding of this essential braking technology.

30 30 brake chamber short stroke, a specialized brake chamber, stands out with its unique design and performance characteristics. Its compact size and reduced stroke length make it an ideal choice for vehicles with limited space or requiring precise braking control.

Brake Chamber Overview

A brake chamber is a crucial component in a compressed air brake system. Its primary function is to convert compressed air energy into mechanical force, which is then used to actuate the brake shoes or pads against the brake drum or disc, ultimately slowing down or stopping the vehicle.

A typical brake chamber consists of a cylindrical housing, a diaphragm or piston, a pushrod, and various seals and fittings. When compressed air enters the chamber, it exerts pressure on the diaphragm or piston, which in turn pushes the pushrod outward.

This motion is then transmitted to the brake shoes or pads, causing them to engage with the brake drum or disc and generate friction, which slows down or stops the vehicle.

Types of Brake Chambers

There are several types of brake chambers, each designed for specific applications and performance requirements:

- Spring Brake Chambers:These chambers incorporate a spring mechanism that applies braking force when air pressure is released, ensuring the vehicle remains stationary even in the event of an air loss.

- Slack Adjuster Brake Chambers:These chambers feature an integrated slack adjuster that automatically adjusts the brake shoe clearance, ensuring optimal braking performance and reducing the need for manual adjustments.

- Quick Release Brake Chambers:These chambers are designed to release air pressure rapidly, allowing for faster brake release and improved vehicle responsiveness.

30 30 Brake Chamber

A 30 30 brake chamber is a type of pneumatic brake chamber commonly used in commercial vehicles such as trucks and buses. It is designed to convert compressed air into mechanical force, which is then used to actuate the brake shoes or pads.

For optimal control over your trailer’s brakes, consider the tow-pro liberty electric brake controller . This advanced controller provides precise braking power, allowing for smooth and safe towing. Its user-friendly interface and compatibility with various trailer types make it an excellent choice for towing enthusiasts.

Specifications

- Bore diameter: 30 mm

- Stroke length: 30 mm

- Operating pressure: 6-12 bar (87-174 psi)

- Push rod diameter: 10 mm

- Weight: approximately 2 kg

Significance of the “30 30” Designation

The “30 30” designation refers to the bore diameter and stroke length of the brake chamber. The bore diameter is the inner diameter of the cylinder in which the piston moves, while the stroke length is the distance the piston travels when the brake chamber is fully actuated.

In this case, both the bore diameter and stroke length are 30 mm, hence the “30 30” designation.

Short Stroke Brake Chambers

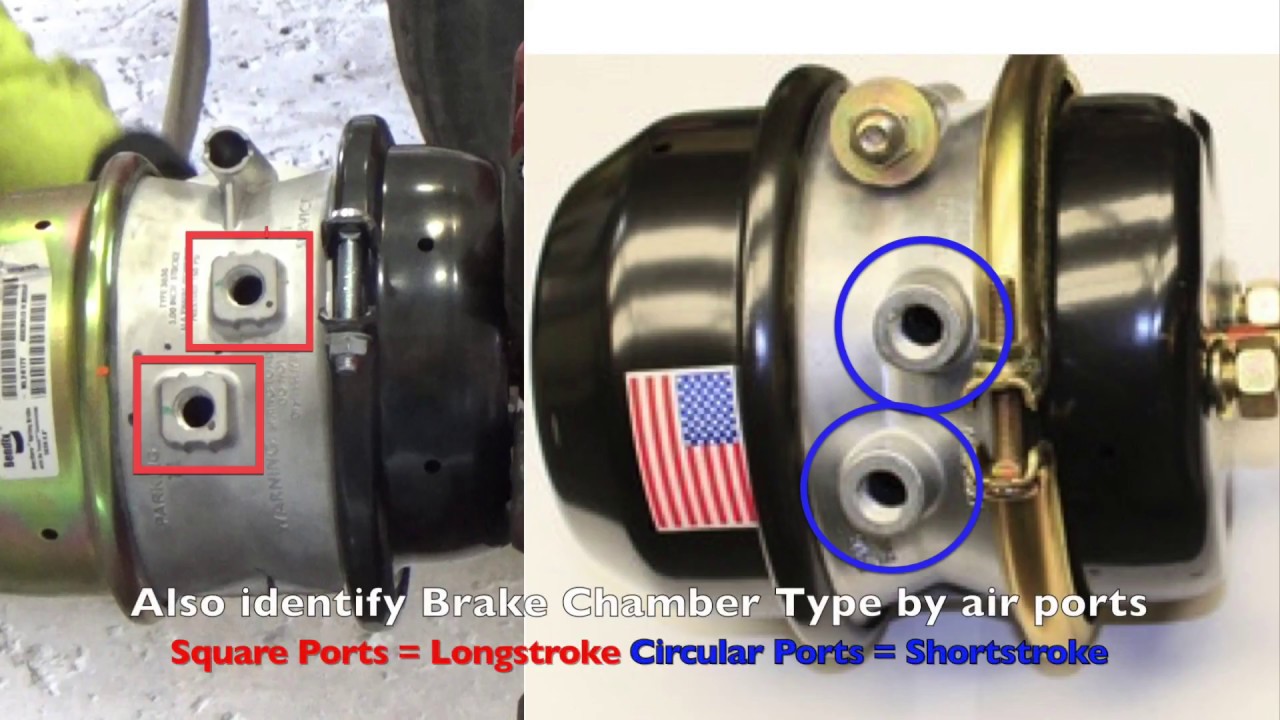

Short stroke brake chambers, as the name suggests, have a shorter stroke length compared to long stroke brake chambers. This design characteristic has several implications for their operation and performance.

Comparison with Long Stroke Brake Chambers

The primary difference between short stroke and long stroke brake chambers lies in their stroke length, which refers to the distance the piston moves within the chamber when activated. Short stroke brake chambers typically have a stroke length of around 1 to 2 inches, while long stroke brake chambers can have a stroke length of up to 4 inches or more.

Due to their shorter stroke length, short stroke brake chambers require less air volume to actuate the piston, resulting in a faster response time. This makes them ideal for applications where quick brake response is crucial, such as in heavy-duty vehicles or racing cars.

In contrast, long stroke brake chambers provide greater piston travel, which can generate higher brake torque. However, their slower response time makes them more suitable for applications where gradual and controlled braking is preferred, such as in passenger cars or light-duty vehicles.

If you’re working on your vehicle’s braking system, you may need a 3 16 compression fitting for brake line . These fittings are essential for connecting brake lines securely and preventing leaks. Ensure you choose the right size and type of fitting for your specific application.

Applications of 30 30 Short Stroke Brake Chambers

30 30 short stroke brake chambers find their niche in various applications where precise and responsive braking is crucial. These chambers are commonly employed in:

Automotive Industry

- Passenger cars: 30 30 short stroke brake chambers are widely used in passenger cars, particularly in rear-wheel drive configurations, where they actuate the rear brakes.

- Light trucks: In light trucks, these chambers are employed to provide reliable and effective braking performance.

- Trailers: Short stroke brake chambers are commonly found in trailers, ensuring controlled and stable braking during towing operations.

Industrial Applications, 30 30 brake chamber short stroke

- Forklifts: The compact size and precise actuation of 30 30 short stroke brake chambers make them suitable for use in forklifts, providing efficient and responsive braking in confined spaces.

- Industrial machinery: These chambers are utilized in various industrial machinery, such as cranes, hoists, and conveyors, where precise and reliable braking is essential for safety and productivity.

Advantages and Disadvantages

30 30 short stroke brake chambers offer several advantages over other types of brake chambers. These advantages include:

- Compact size:30 30 short stroke brake chambers are smaller than other types of brake chambers, which makes them ideal for applications where space is limited.

- Lightweight:30 30 short stroke brake chambers are lightweight, which makes them easy to install and maintain.

- High performance:30 30 short stroke brake chambers provide high performance, even in demanding applications.

However, there are also some potential disadvantages associated with using 30 30 short stroke brake chambers. These disadvantages include:

- Limited stroke length:30 30 short stroke brake chambers have a limited stroke length, which can make them less effective in applications where a long stroke length is required.

- Higher cost:30 30 short stroke brake chambers are more expensive than other types of brake chambers.

Overall, 30 30 short stroke brake chambers offer a number of advantages over other types of brake chambers. However, there are also some potential disadvantages associated with their use. It is important to weigh the advantages and disadvantages carefully before selecting a brake chamber for a particular application.

Maintenance and Troubleshooting

Proper maintenance and troubleshooting are crucial to ensure the optimal performance and longevity of 30 30 short stroke brake chambers.

Recommended Maintenance Procedures

Regular maintenance is essential to keep 30 30 short stroke brake chambers functioning effectively. Here are some recommended maintenance practices:

- Visual Inspection:Regularly inspect the brake chambers for any signs of damage, corrosion, or leaks. Check for loose or worn components and tighten or replace them as necessary.

- Air System Check:Ensure that the air supply to the brake chambers is adequate and free of moisture or contaminants. Regularly check the air lines and fittings for leaks and replace them if needed.

- Lubrication:Lubricate all moving parts of the brake chambers, including the pushrod and diaphragm, according to the manufacturer’s recommendations. This helps reduce friction and wear, extending the brake chamber’s lifespan.

- Diaphragm Inspection:Inspect the diaphragm for cracks, tears, or other damage. A damaged diaphragm can lead to air leaks and reduced braking performance. Replace the diaphragm if necessary.

- Spring Inspection:Check the return springs for any signs of damage or weakening. Weak or broken springs can affect the brake chamber’s release and engagement.

Troubleshooting Common Issues

Despite proper maintenance, 30 30 short stroke brake chambers may encounter issues or failures. Here are some common problems and troubleshooting tips:

- Brake Chamber Not Engaging:Check the air supply to the brake chamber. Ensure that the air pressure is sufficient and that there are no leaks in the air lines or fittings. Inspect the pushrod and diaphragm for damage or binding.

- Brake Chamber Not Releasing:Check the return springs for damage or weakening. Inspect the diaphragm for leaks or tears that may prevent the brake chamber from releasing properly.

- Air Leaks:Inspect the brake chamber for any visible leaks. Check the air lines and fittings for damage or loose connections. Replace any damaged or leaking components.

- Reduced Braking Performance:Check the diaphragm for cracks or tears. Inspect the air system for leaks or moisture contamination. Ensure that the brake chamber is properly adjusted and calibrated.

Regular maintenance and prompt troubleshooting can help ensure the reliability and effectiveness of 30 30 short stroke brake chambers, contributing to overall vehicle safety and performance.

Safety Considerations: 30 30 Brake Chamber Short Stroke

Ensuring the safe operation of 30 30 short stroke brake chambers requires meticulous installation and diligent maintenance practices. Malfunctioning brake chambers pose significant safety hazards and risks, demanding immediate attention and rectification.

Potential Safety Hazards

- Reduced Braking Efficiency:Faulty brake chambers compromise the vehicle’s ability to decelerate effectively, increasing the risk of accidents.

- Uneven Braking:Malfunctioning brake chambers can result in uneven braking forces, leading to vehicle instability and potential loss of control.

- Brake Lock-up:Severe brake chamber malfunctions can cause the brakes to lock, resulting in skidding and loss of steering control.

- Brake Fade:Overheated or worn brake chambers can experience brake fade, reducing braking effectiveness and increasing stopping distances.

Case Studies or Examples

30 30 short stroke brake chambers have been widely used in various industries and applications, showcasing their versatility and effectiveness. Let’s explore some real-world examples and lessons learned from their implementation.

Successful Applications

- Automotive Industry:30 30 short stroke brake chambers have been successfully employed in heavy-duty vehicles, including trucks and buses, providing reliable and responsive braking performance.

- Industrial Machinery:These brake chambers have found applications in industrial machinery, such as cranes, forklifts, and conveyor systems, where precise and efficient braking is crucial.

Challenges and Lessons Learned

- Proper Installation:Ensuring proper installation and adjustment of 30 30 short stroke brake chambers is vital for optimal performance. Inadequate installation can lead to reduced braking efficiency and premature wear.

- Maintenance and Inspection:Regular maintenance and inspections are essential to ensure the longevity and reliability of these brake chambers. Ignoring maintenance can result in decreased braking effectiveness and potential safety hazards.

Ending Remarks

In conclusion, 30 30 brake chamber short stroke stands as a testament to the advancements in braking technology. Its compact design, enhanced performance, and versatility make it a valuable asset in various industries and applications. Understanding its specifications, applications, and maintenance requirements empowers professionals and enthusiasts alike to harness its full potential, ensuring safe and efficient braking systems.

FAQ Summary

What is the significance of the “30 30” designation in 30 30 brake chamber short stroke?

The “30 30” designation refers to the chamber’s diameter and stroke length, both measuring 30 millimeters. This specific combination provides a compact and efficient design.

How do short stroke brake chambers differ from long stroke brake chambers?

Short stroke brake chambers have a shorter stroke length compared to long stroke brake chambers. This results in a more rapid and precise actuation of the brakes, making them suitable for applications requiring quick response times.

What are the advantages of using 30 30 short stroke brake chambers?

30 30 short stroke brake chambers offer several advantages, including compact size, reduced weight, faster response time, and improved braking efficiency.

What maintenance procedures are recommended for 30 30 short stroke brake chambers?

Regular maintenance is crucial for ensuring optimal performance. This includes visual inspections, cleaning, lubrication, and periodic replacement of worn components.