6.7 cummins boost pressure sensor location – Prepare to dive into the depths of the Cummins 6.7L engine as we embark on a quest to locate its elusive boost pressure sensor. Join us on this captivating journey where we unravel the intricacies of this crucial component, unraveling its significance for optimal engine performance.

As we navigate the complexities of diesel engines, we’ll shed light on the fundamental role of boost pressure sensors and delve into the telltale signs of a faulty one. Stay tuned for expert insights, practical troubleshooting tips, and a comprehensive guide to sensor replacement and maintenance.

Cummins 6.7L Engine Overview

The Cummins 6.7L engine is a turbocharged, direct-injection, inline-six diesel engine manufactured by Cummins Inc. It is used in a variety of applications, including pickup trucks, medium-duty trucks, and industrial equipment.

The 6.7L engine has a displacement of 6.7 liters (408 cubic inches) and produces up to 400 horsepower and 1,000 lb-ft of torque. It is known for its reliability, durability, and fuel efficiency.

Applications, 6.7 cummins boost pressure sensor location

The Cummins 6.7L engine is used in a wide range of applications, including:

- Pickup trucks (Ram 2500/3500, Ford F-250/350, Chevrolet Silverado 2500/3500, GMC Sierra 2500/3500)

- Medium-duty trucks (Ford F-450/550, Chevrolet Silverado 4500/5500, GMC Sierra 4500/5500)

- Industrial equipment (construction, mining, agriculture)

Specifications

The Cummins 6.7L engine has the following specifications:

| Specification | Value |

|---|---|

| Displacement | 6.7 liters (408 cubic inches) |

| Power | Up to 400 horsepower |

| Torque | Up to 1,000 lb-ft |

| Fuel system | Direct injection |

| Turbocharger | Variable geometry |

| Emissions | EPA 2010 emissions compliant |

Boost Pressure Sensor Function

In diesel engines, the boost pressure sensor plays a critical role in regulating engine performance and optimizing fuel efficiency. Its primary function is to measure the pressure of the intake air, known as boost pressure, which is generated by the turbocharger.

Accurate boost pressure readings are essential for the engine’s electronic control unit (ECU) to adjust fuel injection, timing, and other engine parameters accordingly. This ensures optimal engine operation, reducing emissions, improving fuel economy, and preventing potential engine damage due to over-boosting or under-boosting.

Sensor Operation

The boost pressure sensor is typically located in the intake manifold or charge air cooler and consists of a diaphragm or strain gauge that detects changes in pressure. As the boost pressure increases, the diaphragm or strain gauge deflects, sending an electrical signal to the ECU.

The ECU then interprets this signal to determine the current boost pressure.

Location of Boost Pressure Sensor on Cummins 6.7L: 6.7 Cummins Boost Pressure Sensor Location

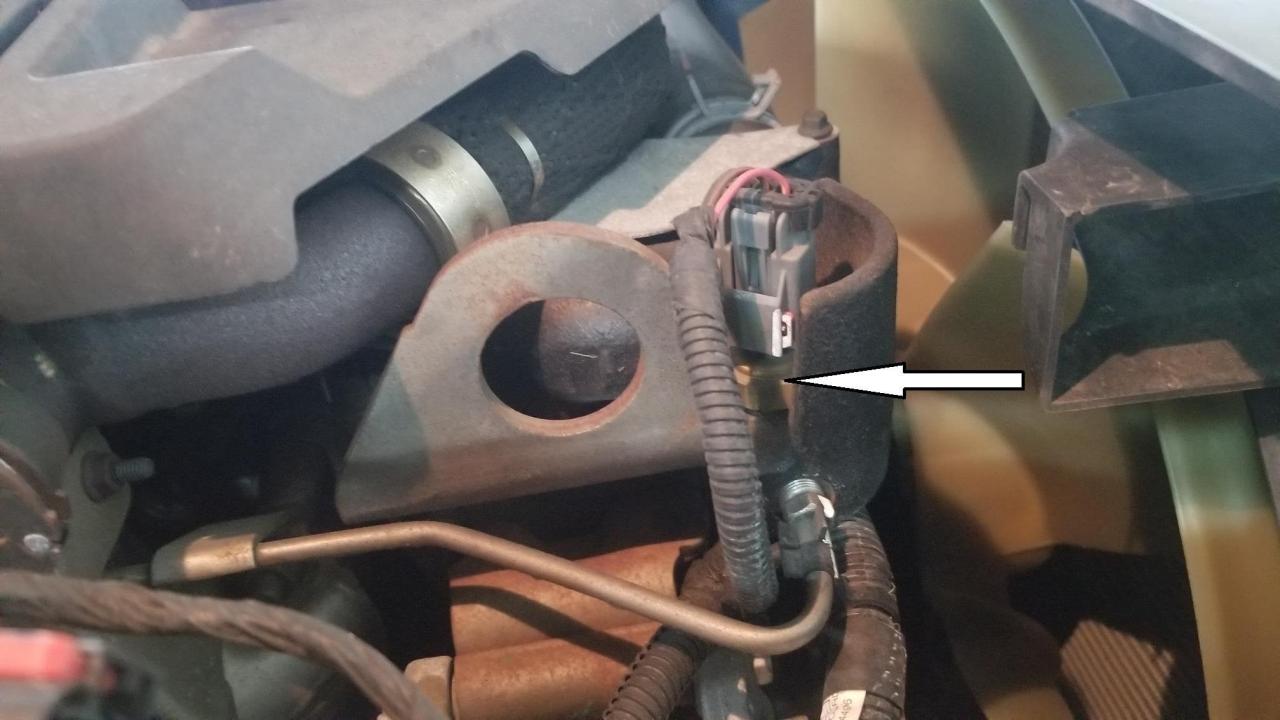

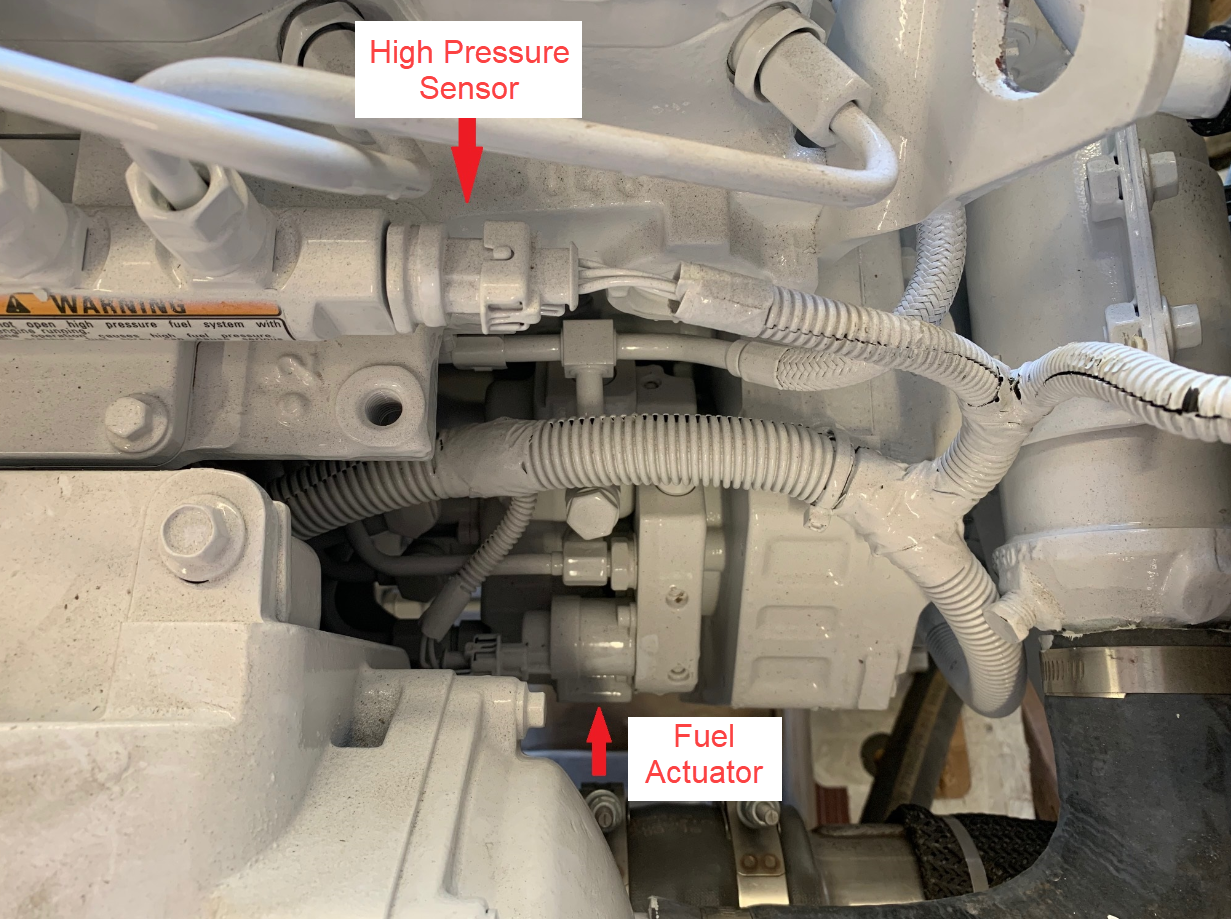

The boost pressure sensor on the Cummins 6.7L engine is typically located on the intake manifold, near the turbocharger. It is a small, round sensor with a single electrical connector. The sensor is responsible for measuring the boost pressure in the intake manifold and sending this information to the engine’s electronic control module (ECM).

The ECM uses this information to adjust the engine’s fuel injection and timing to optimize performance and fuel economy.

Locating the Boost Pressure Sensor

To locate the boost pressure sensor on the Cummins 6.7L engine, follow these steps:

- Open the hood of the vehicle.

- Locate the intake manifold on the front of the engine.

- Follow the intake manifold runner to the turbocharger.

- The boost pressure sensor will be located on the intake manifold, near the turbocharger.

Once you have located the boost pressure sensor, you can disconnect the electrical connector and remove the sensor from the intake manifold. Be careful not to damage the sensor or the intake manifold when removing the sensor.

Testing and Troubleshooting

The boost pressure sensor on the Cummins 6.7L engine plays a crucial role in monitoring and regulating boost pressure. Regular testing and troubleshooting are essential to ensure its proper functioning and prevent potential engine issues.

Several methods can be employed to test the boost pressure sensor. One common approach involves using a digital multimeter to measure the sensor’s electrical resistance. The resistance should fall within the manufacturer’s specified range, typically between 5 and 10 kΩ.

Deviations from this range may indicate a faulty sensor.

Another method involves using a pressure gauge to measure the boost pressure directly. Connect the pressure gauge to the sensor’s vacuum/pressure port and compare the reading to the desired boost pressure. Significant deviations may indicate a faulty sensor or other issues in the boost system.

Common symptoms of a faulty boost pressure sensor include:

- Reduced engine power or performance

- Black smoke from the exhaust

- Check engine light (CEL) illumination

Causes of a faulty boost pressure sensor may include:

- Electrical short or open circuit

- Mechanical damage or contamination

- Sensor diaphragm failure

Troubleshooting a faulty boost pressure sensor involves:

- Inspecting the sensor and wiring harness for any visible damage or loose connections.

- Testing the sensor’s electrical resistance and comparing it to the manufacturer’s specifications.

- Measuring the boost pressure directly using a pressure gauge to verify sensor accuracy.

- Checking for any leaks or restrictions in the boost system that may affect sensor readings.

If the sensor is confirmed to be faulty, it should be replaced promptly to restore proper engine operation and prevent further issues.

Replacement and Installation

Replacing the boost pressure sensor on a Cummins 6.7L engine is a relatively straightforward process that can be completed in a few steps.

Safety Precautions

Before beginning any work, ensure your safety by following these precautions:

- Disconnect the negative battery terminal.

- Allow the engine to cool completely.

- Wear appropriate safety gear, including gloves and eye protection.

Step-by-Step Instructions

1.

-

-*Locate the Boost Pressure Sensor

The boost pressure sensor is typically located on the intake manifold, near the turbocharger. It is usually connected to the intake manifold by a rubber hose.

- 2.

- 3.

- 4.

- 5.

- 6.

- 7.

-*Disconnect the Electrical Connector

Unplug the electrical connector from the boost pressure sensor.

-*Remove the Sensor

Use a wrench or socket to loosen the bolt that secures the boost pressure sensor to the intake manifold. Carefully remove the sensor from its housing.

-*Inspect the O-Ring

Check the O-ring on the new boost pressure sensor for any damage or wear. Replace the O-ring if necessary.

-*Install the New Sensor

Insert the new boost pressure sensor into the housing and tighten the bolt to the specified torque (typically 10-15 ft-lbs).

-*Reconnect the Electrical Connector

Plug the electrical connector back into the boost pressure sensor.

-*Reset the ECM

After replacing the boost pressure sensor, it is recommended to reset the engine control module (ECM) to clear any stored fault codes. This can be done by disconnecting the negative battery terminal for a few minutes.

Torque Specifications

When tightening the bolt that secures the boost pressure sensor to the intake manifold, it is important to use the correct torque. The recommended torque for most Cummins 6.7L engines is 10-15 ft-lbs. Overtightening the bolt can damage the sensor or the intake manifold.

Troubleshooting

If you are experiencing problems with the boost pressure sensor on your Cummins 6.7L engine, there are a few things you can check:

- Check the electrical connection between the sensor and the ECM.

- Inspect the vacuum hose for any leaks or damage.

- Test the boost pressure sensor using a multimeter.

If you are unable to resolve the issue, it is recommended to consult with a qualified mechanic.

Maintenance and Prevention

Regular maintenance is crucial for the optimal performance and longevity of the boost pressure sensor and its related components. Cleaning and inspecting the sensor and its connections at recommended intervals can prevent issues and ensure accurate readings. Neglecting maintenance can lead to sensor malfunctions, inaccurate boost pressure readings, reduced engine performance, and potential damage to the engine and turbocharger.

Inspection and Cleaning

Inspect the boost pressure sensor and its connections for any signs of damage, corrosion, or loose connections. Clean the sensor using a suitable cleaner and a soft cloth, ensuring no debris or contaminants remain. Refer to the manufacturer’s recommendations for specific cleaning intervals and procedures.

Regular Checks

Regularly check the boost pressure sensor and its connections for any issues. This includes inspecting the wiring harness for damage or loose connections, ensuring the sensor is securely mounted, and verifying that the vacuum line is properly connected and free of leaks.

Potential Consequences of Neglecting Maintenance

Neglecting maintenance can have severe consequences for the boost pressure sensor and its related components. It can lead to inaccurate boost pressure readings, which can affect engine performance and fuel efficiency. In severe cases, it can cause the turbocharger to overboost, potentially leading to engine damage.

Additionally, neglecting maintenance can shorten the lifespan of the boost pressure sensor and its related components.

Closing Notes

In conclusion, mastering the location, function, and maintenance of the boost pressure sensor empowers you to maintain the health of your Cummins 6.7L engine. Remember, timely attention to this vital component ensures a seamless driving experience, maximizing performance and extending the life of your beloved vehicle.

Commonly Asked Questions

Where is the boost pressure sensor typically located on a Cummins 6.7L engine?

Typically, you’ll find the boost pressure sensor nestled on the intake manifold, close to the turbocharger.

What are the symptoms of a faulty boost pressure sensor?

A faulty sensor can manifest in various ways, including reduced engine power, increased fuel consumption, and excessive smoke emissions.

How can I test the boost pressure sensor?

Testing involves using a scan tool to monitor sensor readings or applying a vacuum pump to check for leaks and proper signal output.

Is it essential to replace the boost pressure sensor if it fails?

Yes, replacing a faulty sensor is crucial to restore optimal engine performance and prevent potential damage.