Introducing the Best Professional Knife Sharpener, a comprehensive guide that delves into the art of keeping your knives razor-sharp. From comparing popular sharpeners to mastering advanced techniques, this guide is your ultimate resource for achieving unparalleled sharpness.

In this guide, we’ll explore the various types of professional knife sharpeners, their features and benefits, and the proper sharpening techniques to ensure optimal performance. We’ll also cover safety considerations, maintenance tips, and troubleshooting common sharpening issues.

Product Comparison

The market offers a wide array of professional knife sharpeners, each with its unique set of features and capabilities. Understanding the key differences between these sharpeners is crucial for making an informed decision.

When comparing professional knife sharpeners, several factors should be taken into consideration:

Material

- Sharpeners can be made from various materials, including ceramic, diamond, and tungsten carbide.

- Ceramic sharpeners are durable and provide a fine edge, but they can be more expensive.

- Diamond sharpeners are extremely hard and long-lasting, making them suitable for sharpening hard steels.

- Tungsten carbide sharpeners offer a compromise between ceramic and diamond, providing both durability and affordability.

Grit

- Grit refers to the coarseness or fineness of the sharpening surface.

- A lower grit number indicates a coarser surface, which removes more material and creates a sharper edge.

- A higher grit number indicates a finer surface, which refines the edge and creates a smoother finish.

Angle Guides

- Angle guides help maintain the correct sharpening angle, which is crucial for achieving a sharp and durable edge.

- Sharpeners with built-in angle guides are easier to use and ensure consistent results.

- Sharpeners without angle guides require more skill and practice to achieve the desired edge.

Ease of Use

- The ease of use of a sharpener is important for both beginners and experienced users.

- Sharpeners with ergonomic handles and non-slip bases provide a comfortable and stable grip.

- Sharpeners with multiple sharpening slots allow for easy sharpening of different types of knives.

Types of Sharpeners

Professional knife sharpeners come in a variety of types, each with its own advantages and disadvantages. The most common types include electric sharpeners, manual sharpeners, honing steels, and sharpening stones.

The best type of sharpener for you will depend on your individual needs and preferences. If you’re looking for a quick and easy way to sharpen your knives, an electric sharpener is a good option. However, if you’re looking for more control over the sharpening process, a manual sharpener or sharpening stone is a better choice.

Electric Sharpeners

- Electric sharpeners are the most convenient and easiest to use type of sharpener.

- They are typically small and lightweight, making them easy to store and transport.

- Electric sharpeners use a rotating abrasive wheel to sharpen knives.

- The speed of the abrasive wheel can be adjusted to accommodate different types of knives.

- Electric sharpeners are relatively inexpensive, making them a good option for home cooks.

Manual Sharpeners

- Manual sharpeners require more skill to use than electric sharpeners.

- They are typically larger and heavier than electric sharpeners.

- Manual sharpeners use a fixed abrasive surface to sharpen knives.

- The angle of the abrasive surface can be adjusted to accommodate different types of knives.

- Manual sharpeners are more expensive than electric sharpeners, but they offer more control over the sharpening process.

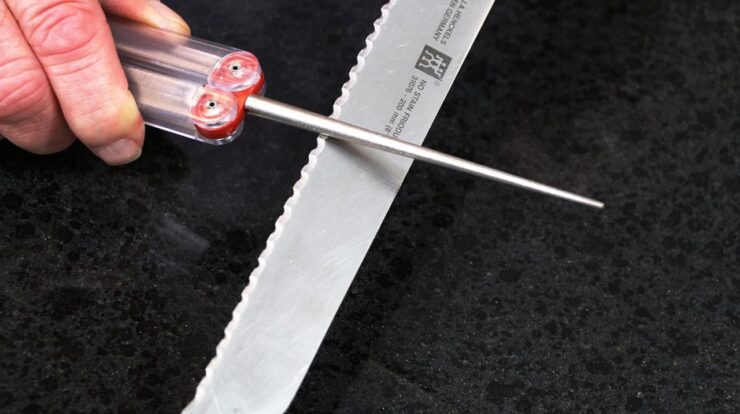

Honing Steels

- Honing steels are used to maintain the edge of a knife, not to sharpen it.

- They are typically made of steel or ceramic.

- Honing steels are used by drawing the knife blade along the steel in a smooth, even motion.

- Honing steels help to align the edge of the knife and remove any burrs.

- Honing steels are a good option for home cooks who want to keep their knives sharp without having to use a sharpener.

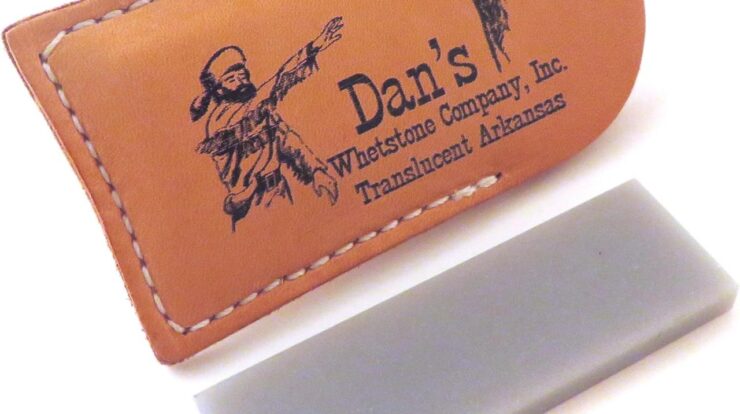

Sharpening Stones

- Sharpening stones are the most traditional type of sharpener.

- They are typically made of natural or synthetic materials, such as sandstone, whetstone, or diamond.

- Sharpening stones are used by rubbing the knife blade against the stone in a circular motion.

- The grit of the sharpening stone determines how fine or coarse the edge of the knife will be.

- Sharpening stones require more skill to use than other types of sharpeners, but they offer the most control over the sharpening process.

Maintenance and Care

Maintaining and caring for your professional knife sharpener is essential to ensure its optimal performance and longevity. Regular cleaning and lubrication are crucial for its smooth operation.

Cleaning, Best professional knife sharpener

- Clean the sharpener’s surfaces with a damp cloth or brush after each use.

- Remove any metal shavings or debris from the sharpening slots or guides.

- If the sharpener has a water tray, empty and clean it regularly to prevent rust.

Lubrication

- Lubricate the moving parts of the sharpener, such as gears or bearings, according to the manufacturer’s instructions.

- Use a light oil or grease specifically designed for knife sharpeners.

- Apply a small amount of lubricant to the moving parts and wipe off any excess.

Features and Benefits

:max_bytes(150000):strip_icc()/knife-sharpeners-FT-BLOG0120-dda47468b1a447ecac20755e89ec12f3.jpg)

Professional knife sharpeners vary in their features and benefits, catering to different sharpening needs and preferences. Understanding these aspects helps in selecting the most suitable sharpener for your specific requirements.

To facilitate a comprehensive comparison, we have compiled a table highlighting the key features and corresponding benefits of different types of professional knife sharpeners:

Speed

- Electric sharpeners: Offer rapid sharpening, ideal for quickly restoring the sharpness of multiple knives.

- Manual sharpeners: Require more effort and time but provide greater control over the sharpening angle and pressure.

Precision

- Water stones: Allow for precise sharpening, enabling you to achieve a specific edge angle and sharpness level.

- Ceramic rods: Provide consistent sharpening, maintaining the original edge angle of the knife.

Durability

- Diamond sharpeners: Highly durable and long-lasting, suitable for sharpening hard steels and heavy-duty use.

- Ceramic sharpeners: Durable and corrosion-resistant, offering a long lifespan.

Versatility

- Electric sharpeners: Can handle a wide range of knives, including serrated blades and scissors.

- Manual sharpeners: Offer greater flexibility in sharpening different types of knives and tools, including axes and chisels.

Professional Uses: Best Professional Knife Sharpener

Professional knife sharpeners cater to the specialized needs of various industries where sharp knives are essential tools. These industries include:

Culinary Arts

- Professional chefs require razor-sharp knives for precise cutting, dicing, and slicing.

- Knife sharpeners designed for culinary professionals offer precision angles and fine-grit abrasives to maintain the sharpness and edge geometry of their knives.

Butchers

- Butchers need knives that can handle heavy-duty tasks like cutting through meat and bone.

- Sharpeners for butchers are designed to create durable edges that can withstand the demands of their work.

Carpenters

- Carpenters rely on sharp knives for precise cuts and shaping of wood.

- Knife sharpeners for carpenters are typically designed to handle both woodworking knives and chisels.

Outdoor Enthusiasts

- Outdoor enthusiasts, such as hunters and campers, need reliable knives for various tasks.

- Sharpeners designed for outdoor use are portable, durable, and capable of sharpening a wide range of knife types.

Sharpening Angles

Sharpening angles play a crucial role in determining the performance and longevity of your knives. Different types of knives require specific sharpening angles to optimize their cutting abilities.

The sharpening angle refers to the angle at which the blade meets the sharpening stone or steel. A smaller angle creates a sharper edge but may be more fragile, while a larger angle results in a more durable edge but may not be as sharp.

Chef’s Knives

Chef’s knives typically require a sharpening angle between 15 and 20 degrees per side. This angle provides a balance between sharpness and durability, making it suitable for a wide range of cutting tasks.

Paring Knives

Paring knives, used for precision work, benefit from a slightly sharper edge. A sharpening angle of 12 to 15 degrees per side is recommended for these knives, allowing for intricate cuts and delicate slicing.

Hunting Knives

Hunting knives require a more durable edge to withstand the rigors of outdoor use. A sharpening angle of 20 to 25 degrees per side is ideal for these knives, providing a balance between sharpness and resilience.

Advanced Sharpening Techniques

Professional knife sharpeners employ advanced techniques to achieve exceptional sharpness and maintain optimal blade performance. These techniques include:

- Stropping:Stropping involves running the blade over a smooth, flexible surface, such as leather or canvas, coated with a fine abrasive. This aligns the edge and removes any burrs, resulting in a refined and polished finish.

- Honing:Honing uses a steel rod or stone to realign the blade’s edge and remove any microscopic burrs or imperfections. It helps maintain the sharpness of the blade over time and extends its lifespan.

- Burr removal:After sharpening, a small burr may form on the opposite side of the edge. Removing this burr is crucial to ensure a clean and effective cutting edge. Techniques for burr removal include stropping, honing, or gently running the blade over a piece of cardboard.

Mastering these advanced sharpening techniques requires practice and experience. By incorporating them into their sharpening routines, professional knife sharpeners achieve the highest levels of sharpness and performance from their blades.

Troubleshooting Common Sharpening Issues

Sharpening knives is a necessary task to maintain their sharpness and functionality. However, it can sometimes be challenging, and various issues can arise during the process. Here are some common problems that may occur and how to resolve them:

Uneven Sharpening

Uneven sharpening occurs when one side of the knife is sharpened more than the other, resulting in an uneven edge. This can happen due to inconsistent pressure or angle while sharpening. To fix this, apply equal pressure on both sides of the knife and maintain a consistent angle throughout the sharpening process.

Cozy up with an electric blanket queen during chilly nights. Its soft, plush material will keep you warm and comfortable all night long. Indulge in a restful slumber while the blanket evenly distributes heat, ensuring optimal warmth without overheating.

Burrs

Burrs are small, metal shavings that form on the edge of the knife during sharpening. They can cause the knife to feel rough or snag on materials. To remove burrs, use a honing steel or a fine-grit stone to gently run along the edge of the knife at a slight angle.

This will remove the burrs and create a smooth, sharp edge.

If you’re looking for a way to stay warm and cozy on chilly nights, consider investing in an electric blanket queen . These blankets provide even heat distribution, ensuring you stay comfortable all night long. Plus, they’re energy-efficient, so you can enjoy a warm bed without worrying about high energy bills.

Damage to the Knife

In some cases, improper sharpening techniques can damage the knife. Overheating the knife due to excessive friction or using too coarse a grit stone can cause the metal to become brittle and weak. To prevent damage, use a sharpening stone with the appropriate grit for your knife and apply moderate pressure while sharpening.

Epilogue

Whether you’re a culinary professional, a butcher, a carpenter, or simply an outdoor enthusiast, this guide will empower you with the knowledge and skills to keep your knives sharp and ready for any task. Embrace the art of knife sharpening and elevate your culinary skills or craft to new heights.

Popular Questions

What are the key factors to consider when choosing a professional knife sharpener?

Material, grit, angle guides, ease of use, and durability.

What are the different types of professional knife sharpeners?

Electric sharpeners, manual sharpeners, honing steels, and sharpening stones.

How do I properly sharpen a knife using a professional sharpener?

Maintain the correct angle and apply consistent pressure, following the specific instructions for your chosen sharpener.