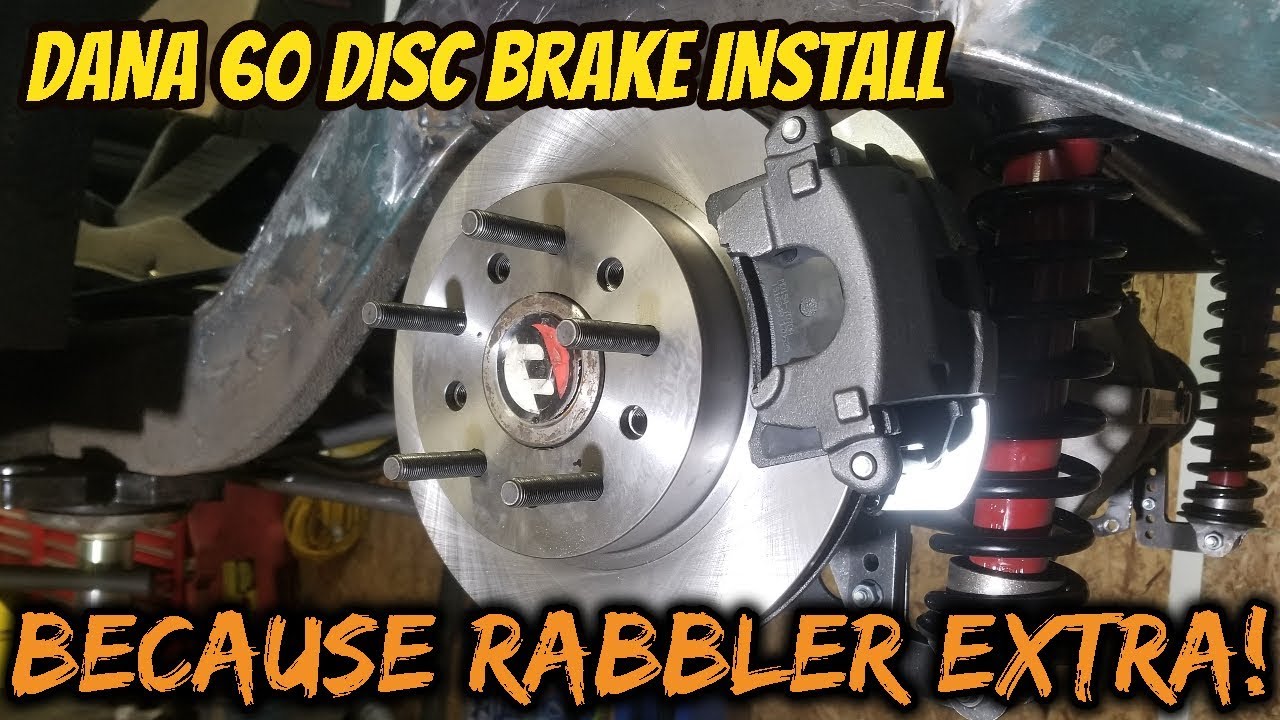

Embark on a transformative journey with the Dana 60 rear disc brake conversion, a revolution in off-road braking technology. Experience enhanced stopping power, reduced fade, and improved overall reliability.

Delve into the intricacies of this conversion, exploring the benefits, components, installation process, troubleshooting techniques, and performance comparisons that will empower you to conquer any terrain with confidence.

Overview of Dana 60 Rear Disc Brake Conversion

Upgrading your Dana 60 rear axle with disc brakes is a popular modification for off-road enthusiasts. Disc brakes offer several advantages over traditional drum brakes, including improved stopping power, reduced fade, and better modulation. This conversion can significantly enhance the safety and performance of your off-road vehicle.

The Dana 60 axle has been a mainstay in the off-road community for decades. Its robust construction and wide availability make it an ideal choice for heavy-duty applications. Several different types of Dana 60 rear disc brake conversion kits are available, allowing you to customize the conversion to your specific needs and budget.

Types of Dana 60 Rear Disc Brake Conversion Kits

There are two main types of Dana 60 rear disc brake conversion kits: bolt-on and weld-on. Bolt-on kits are easier to install, but they may not be as strong as weld-on kits. Weld-on kits require more fabrication, but they are typically stronger and more durable.

When choosing a Dana 60 rear disc brake conversion kit, it is important to consider the following factors:

- Your budget

- Your skill level

- The intended use of your vehicle

With careful planning and execution, a Dana 60 rear disc brake conversion can be a rewarding project that will improve the performance and safety of your off-road vehicle.

For those who demand even more stopping power, the sterling 10.25 disc brake conversion is an excellent choice. This upgrade replaces your stock drum brakes with high-performance disc brakes, providing superior stopping power and reduced fade. It’s the perfect solution for those who frequently tow heavy loads or drive in demanding conditions.

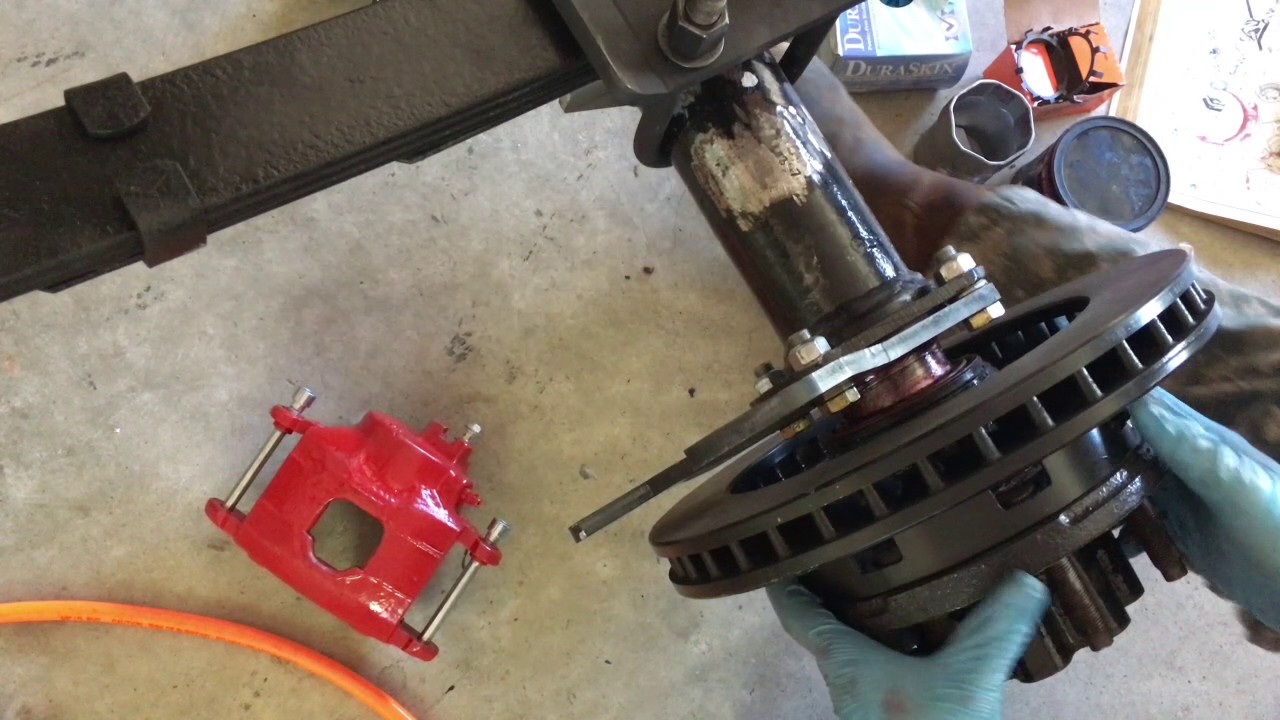

Components Required for Dana 60 Rear Disc Brake Conversion

The conversion of a Dana 60 rear axle from drum brakes to disc brakes requires a comprehensive set of components to ensure proper functionality and safety. These components can be categorized into calipers, rotors, brackets, and hardware.

Calipers

Calipers are the primary components responsible for applying hydraulic pressure to the brake pads, which in turn generate friction against the rotors to slow down or stop the vehicle. In a Dana 60 rear disc brake conversion, specific calipers are required to match the axle’s design and provide optimal braking performance.

Rotors

Rotors are the discs that rotate with the axle and provide a surface for the brake pads to grip. They are typically made of cast iron or steel and must be compatible with the chosen calipers and axle configuration. The selection of rotors depends on factors such as the vehicle’s weight, intended use, and desired braking characteristics.

Brackets

Brackets are essential for mounting the calipers onto the axle housing. They are designed to provide a secure and stable connection between the calipers and the axle, ensuring proper alignment and functioning of the braking system. The brackets must be compatible with the specific axle model and caliper type being used.

Hardware

Hardware encompasses various components, including brake pads, brake lines, and mounting bolts, which are necessary to complete the disc brake conversion. Brake pads are the friction material that makes contact with the rotors, and their selection depends on the intended use of the vehicle and desired braking performance.

Brake lines convey hydraulic fluid from the master cylinder to the calipers, and they must be sized and routed appropriately for the specific application. Mounting bolts secure the calipers and brackets to the axle housing, ensuring a solid and reliable connection.

Installation Process for Dana 60 Rear Disc Brake Conversion

The installation process for a Dana 60 rear disc brake conversion kit requires meticulous attention to detail and adherence to specific steps. This guide provides comprehensive instructions, complemented by clear diagrams and illustrations, to ensure a successful installation.

If you’re looking for an easy way to upgrade your braking system, consider the tow-pro liberty electric brake controller . It’s a great option for those who want to improve their towing experience without breaking the bank. With its simple installation and intuitive design, you’ll be able to enjoy a safer and more controlled ride in no time.

Step 1: Preparation and Disassembly

Before commencing the installation, gather all necessary tools and materials. Remove the rear wheels, brake drums, and backing plates. Inspect the axle shafts and bearings for any damage or wear, and replace them if required.

Step 2: Installing the Brackets and Calipers

Mount the brake caliper brackets onto the axle housing using the provided bolts. Securely tighten the bolts to the specified torque. Install the brake calipers onto the brackets and tighten the mounting bolts.

Step 3: Connecting the Brake Lines

Connect the brake lines to the calipers. Use new brake lines if necessary, and ensure they are routed correctly to avoid any kinks or restrictions. Tighten the brake line fittings securely.

Step 4: Installing the Rotors

Slide the brake rotors onto the axle shafts. Ensure the rotors are properly seated and aligned. Install the lug nuts and tighten them to the specified torque.

Step 5: Bleeding the Brakes

Bleed the brake system to remove any air from the lines. Use a brake bleeding kit and follow the manufacturer’s instructions for the bleeding procedure.

Step 6: Final Assembly

Reinstall the rear wheels and tighten the lug nuts. Check the brake fluid level and top it off if necessary. Test the brakes by applying pressure to the brake pedal. Ensure the brakes engage smoothly and effectively.

Troubleshooting Common Issues with Dana 60 Rear Disc Brake Conversion

Converting a Dana 60 rear axle to disc brakes is a popular upgrade for improved braking performance. However, some common issues may arise during or after the conversion process.

This section will provide detailed troubleshooting steps for common problems, categorized into brake noise, pedal pulsation, and fluid leaks.

Brake Noise

Brake noise can be caused by various factors. Here are some common issues and their solutions:

- Squealing noise:This is often caused by worn or contaminated brake pads. Replace the pads and clean the caliper piston and bracket surfaces.

- Grinding noise:This could indicate worn brake rotors. Inspect the rotors for excessive wear and replace them if necessary.

- Chattering noise:This is typically caused by uneven pad wear or warped rotors. Check the pad wear and rotor condition, and replace any damaged components.

Performance Comparison: Drum Brakes vs. Disc Brakes on Dana 60

Drum brakes and disc brakes represent two distinct braking systems commonly found on Dana 60 axles. While both systems serve the purpose of decelerating or stopping a vehicle, they differ in their design, operation, and performance characteristics. This section delves into a comparative analysis of drum brakes and disc brakes, evaluating their respective advantages and disadvantages in the context of a Dana 60 axle.

Stopping Power

Stopping power refers to the ability of a brake system to bring a vehicle to a complete stop from a given speed. Disc brakes generally exhibit superior stopping power compared to drum brakes. This is primarily attributed to the larger surface area of the brake pads in disc brakes, which allows for greater friction and heat dissipation.

Additionally, disc brakes are less prone to brake fade, a phenomenon where the braking effectiveness diminishes due to excessive heat buildup.

Fade Resistance

Brake fade occurs when the brake system experiences a loss of effectiveness due to excessive heat buildup. Disc brakes possess better fade resistance than drum brakes. The open design of disc brakes allows for better heat dissipation, preventing the brake components from overheating and losing their braking capacity.

Whether you’re tackling tough terrain with your trailer or just cruising around town, having reliable brakes is essential. For electric brake controllers, the Tow-Pro Liberty is a top choice, providing precise and smooth braking power. And if you’re looking to upgrade your braking system, the Sterling 10.25 Disc Brake Conversion is a great option, offering increased stopping power and improved handling.

This is particularly advantageous in situations involving repeated or prolonged braking, such as towing heavy loads or descending steep grades.

Reliability

Reliability refers to the ability of a brake system to function consistently and effectively over an extended period of time. Both drum brakes and disc brakes offer good reliability when properly maintained. However, disc brakes tend to be more reliable in harsh operating conditions, such as extreme temperatures or exposure to water and dirt.

The enclosed nature of drum brakes makes them more susceptible to contamination and corrosion, which can compromise their performance and lifespan.

Ending Remarks: Dana 60 Rear Disc Brake Conversion

The Dana 60 rear disc brake conversion stands as a testament to the relentless pursuit of off-road excellence. By embracing this upgrade, you unlock a world of enhanced braking capabilities, paving the way for unforgettable adventures.

FAQ

Q: What are the advantages of disc brakes over drum brakes?

A: Disc brakes provide superior stopping power, reduced fade resistance, and improved heat dissipation.

Q: What components are required for a Dana 60 rear disc brake conversion?

A: The conversion typically includes calipers, rotors, brackets, brake lines, and hardware.

Q: How difficult is it to install a Dana 60 rear disc brake conversion?

A: The installation process requires moderate mechanical skills and typically takes several hours to complete.