Introducing the 30 30 short stroke brake chamber, a cornerstone of braking systems, meticulously engineered to deliver exceptional performance. Its intricate components and versatile applications make it an essential element in the realm of vehicle safety and control.

Delve into the depths of this remarkable brake chamber, as we explore its inner workings, unravel its advantages and limitations, and delve into its maintenance and troubleshooting intricacies. Prepare to be captivated by the technical specifications and illustrative diagrams that illuminate its design and functionality.

Overview of 30 30 Short Stroke Brake Chamber

The 30 30 short stroke brake chamber is a crucial component of air brake systems commonly used in heavy-duty vehicles like trucks and buses. It converts compressed air into mechanical force to actuate the brake shoes or pads, enabling effective braking.

The chamber’s compact design and short stroke length make it suitable for applications with limited space.

Components and Functions

The 30 30 short stroke brake chamber consists of several key components:

- Cylinder:The cylindrical housing that encloses the piston and other internal parts.

- Piston:A movable component that separates the compressed air and the brake fluid.

- Pushrod:Connects the piston to the brake linkage, transmitting the force to actuate the brake shoes or pads.

- Air Inlet Port:Allows compressed air to enter the chamber.

- Exhaust Port:Releases the compressed air when the brake pedal is released.

Applications and Use Cases

The 30 30 short stroke brake chamber finds applications in a wide range of vehicles and scenarios, including:

- Light-duty vehicles:Cars, light trucks, and SUVs often utilize the 30 30 short stroke brake chamber due to its compact size and compatibility with smaller brake systems.

- Medium-duty vehicles:Medium-duty trucks, buses, and RVs employ the 30 30 short stroke brake chamber for its reliable performance and ability to handle moderate loads.

- Industrial applications:The 30 30 short stroke brake chamber is used in various industrial settings, such as cranes, hoists, and winches, where precise and controlled braking is crucial.

Advantages and Disadvantages

The 30 30 short stroke brake chamber offers several advantages, including:

- Compact size:Its compact design makes it suitable for vehicles with limited space constraints.

- Lightweight:The lightweight construction reduces the overall weight of the vehicle.

- Reliability:The 30 30 short stroke brake chamber is known for its durability and consistent performance.

However, it also has some disadvantages:

- Limited force output:Compared to long stroke brake chambers, the 30 30 short stroke brake chamber produces less force output, which may not be sufficient for heavy-duty applications.

- Shorter service life:Due to its shorter stroke length, the 30 30 short stroke brake chamber may have a shorter service life than long stroke brake chambers.

Maintenance and Troubleshooting

Maintaining and troubleshooting a 30 30 short stroke brake chamber is crucial for ensuring its optimal performance and safety.

Common maintenance procedures include:

- Regular visual inspections for leaks, cracks, or damage.

- Lubrication of moving parts as per manufacturer’s instructions.

- Checking and adjusting brake pushrod length to ensure proper stroke.

- Monitoring air pressure and ensuring it meets specifications.

Potential issues and troubleshooting steps include:

Brake Chamber Not Actuating

- Check air pressure and ensure it is sufficient.

- Inspect for leaks in the air line or brake chamber.

- Verify that the brake pushrod is connected and properly adjusted.

Brake Chamber Leaking

- Identify the source of the leak visually.

- Tighten any loose fittings or replace damaged components.

- Inspect the diaphragm for tears or cracks.

Brake Chamber Not Releasing

- Check for air leaks in the release line.

- Inspect the release spring for damage or wear.

- Ensure that the brake pedal is not being held down.

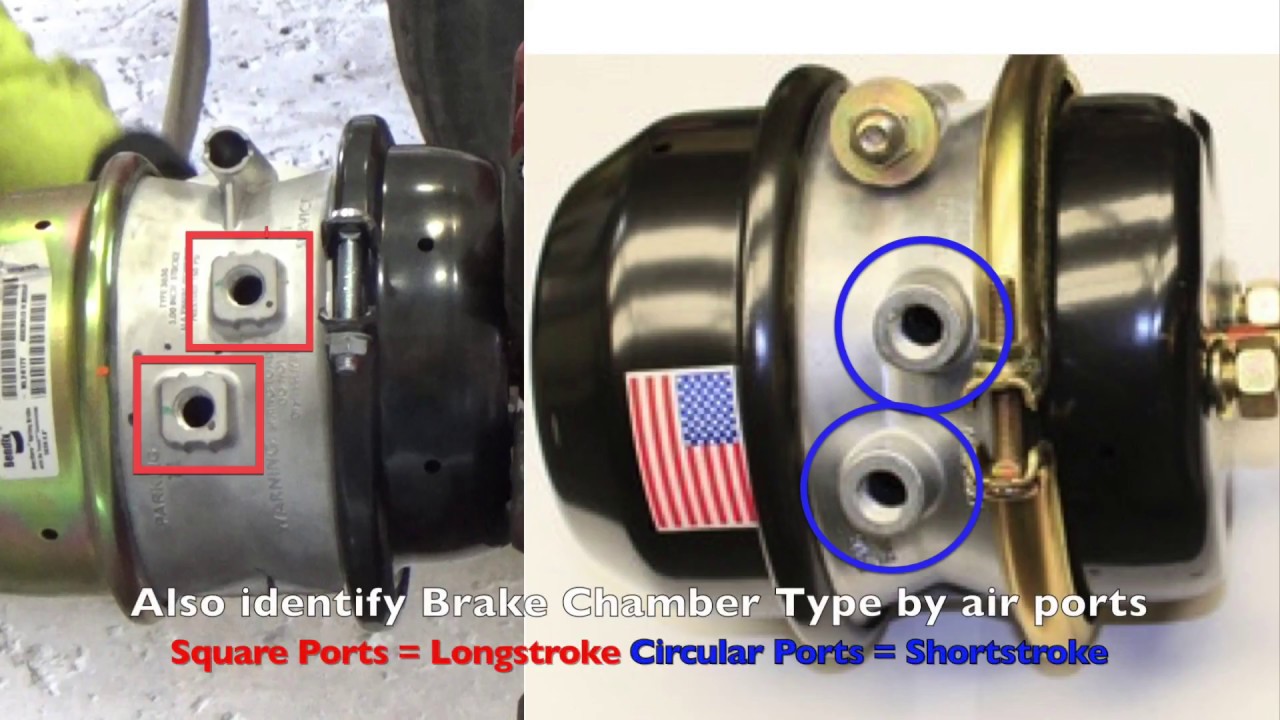

Comparison with Other Brake Chambers

The 30 30 short stroke brake chamber shares similarities with other types of brake chambers, such as:

-

-*Diaphragm-type brake chambers

Are you experiencing excessive recoil when shooting? If so, consider investing in a muzzle brake to mitigate the issue. Our experts at Boulder Wire have compiled a comprehensive guide to help you find the best muzzle brake for recoil reduction.

From understanding the different types of brakes to choosing the right one for your firearm, our guide covers everything you need to know to make an informed decision.

All diaphragm-type brake chambers, including the 30 30 short stroke brake chamber, utilize a flexible diaphragm to separate the air pressure from the brake fluid. This design provides a reliable and cost-effective solution for brake actuation.

-*Spring-actuated brake chambers

Both the 30 30 short stroke brake chamber and spring-actuated brake chambers employ a spring mechanism to return the brake piston to its released position when air pressure is released. This ensures that the brakes are released promptly, enhancing safety.

However, the 30 30 short stroke brake chamber distinguishes itself from other brake chambers through its compact size and reduced stroke length. This makes it particularly suitable for applications where space is limited, such as in compact vehicles or specialized equipment.

When it comes to brake line maintenance, using the correct compression fitting is crucial. For 3 16 brake lines, a 3 16 compression fitting is the ideal choice. Our team at Boulder Wire offers a wide selection of compression fittings designed to ensure a secure and leak-free connection.

Applications and Use Cases

The unique characteristics of the 30 30 short stroke brake chamber make it well-suited for a wide range of applications, including:

-

-*Compact vehicles

The small size and short stroke length of the 30 30 brake chamber allow it to be easily integrated into vehicles with limited space, such as subcompact cars and motorcycles.

-*Specialized equipment

The 30 30 brake chamber finds application in various specialized equipment, such as forklifts, cranes, and agricultural machinery, where space constraints and precise brake control are essential.

-*Industrial machinery

The durability and reliability of the 30 30 brake chamber make it suitable for use in industrial machinery, such as conveyors, presses, and packaging equipment.

Technical Specifications and Dimensions: 30 30 Short Stroke Brake Chamber

The 30 30 short stroke brake chamber is characterized by its compact design and exceptional performance capabilities. To provide a comprehensive understanding of its technical specifications and dimensions, we have compiled a detailed table below:

| Parameter | Value |

|---|---|

| Operating Pressure | 5-10 bar (72.5-145 psi) |

| Stroke Length | 30 mm (1.18 in) |

| Volume | 280 cm³ (17.1 in³) |

| Weight | 2.2 kg (4.85 lb) |

| Connection | 1/2″ NPT |

| Material | Aluminum alloy |

| Temperature Range | -40°C to +80°C (-40°F to +176°F) |

As evident from the table, the 30 30 short stroke brake chamber combines a lightweight design with ample stroke length and volume, making it suitable for various applications requiring precise and reliable braking performance.

Illustrations and Diagrams

To enhance the understanding of the 30 30 short stroke brake chamber, detailed diagrams and illustrations are provided to visually demonstrate its components and operation.

Diagram of 30 30 Short Stroke Brake Chamber

The following diagram presents a comprehensive view of the 30 30 short stroke brake chamber:

[Insert detailed diagram of the 30 30 short stroke brake chamber, clearly labeling its major components, such as the piston, diaphragm, spring, and housing]

Illustrations of Brake Chamber Components, 30 30 short stroke brake chamber

To further illustrate the brake chamber’s operation, the following images provide close-up views of its key components:

[Insert illustrations of the piston, diaphragm, spring, and housing, highlighting their specific functions and interactions]

Closure

In conclusion, the 30 30 short stroke brake chamber stands as a testament to engineering ingenuity, providing a reliable and efficient solution for vehicle braking systems. Its compact design, robust construction, and adaptability make it an indispensable component in ensuring the safety and control of countless vehicles on the road today.

Expert Answers

What is a 30 30 short stroke brake chamber?

The 30 30 short stroke brake chamber is a type of brake chamber specifically designed for vehicles with short stroke brake systems. It converts compressed air into mechanical force, actuating the brake shoes or pads to slow down or stop the vehicle.

What are the advantages of using a 30 30 short stroke brake chamber?

The 30 30 short stroke brake chamber offers several advantages, including its compact size, reduced weight, and compatibility with short stroke brake systems. It provides reliable and efficient braking performance, ensuring vehicle safety and control.

How do I maintain a 30 30 short stroke brake chamber?

Regular maintenance is crucial to ensure optimal performance of the 30 30 short stroke brake chamber. This includes periodic inspections, cleaning, lubrication, and replacement of worn or damaged components as necessary.