When it comes to the inner workings of a vehicle, the O2 sensor stands as a crucial component, playing a vital role in ensuring optimal engine performance. But where exactly does this enigmatic sensor reside? Embark on a journey with us as we delve into the fascinating realm of O2 sensor location, uncovering its typical whereabouts and the intriguing factors that influence its placement.

In most vehicles, you’ll typically find the O2 sensor nestled within the exhaust system, strategically positioned to monitor the oxygen levels in the exhaust gases. Depending on the vehicle model and design, it can be located either upstream or downstream of the catalytic converter.

Understanding these common locations is essential for effective maintenance and troubleshooting.

Sensor Location

Oxygen sensors are typically located in the exhaust system of a vehicle, where they can measure the oxygen content in the exhaust gases. This information is used by the engine control unit (ECU) to adjust the air-fuel ratio, ensuring that the engine is running efficiently and meeting emission standards.

The specific location of the O2 sensors in a vehicle can vary depending on the make and model of the vehicle. However, there are some common locations where O2 sensors are typically placed:

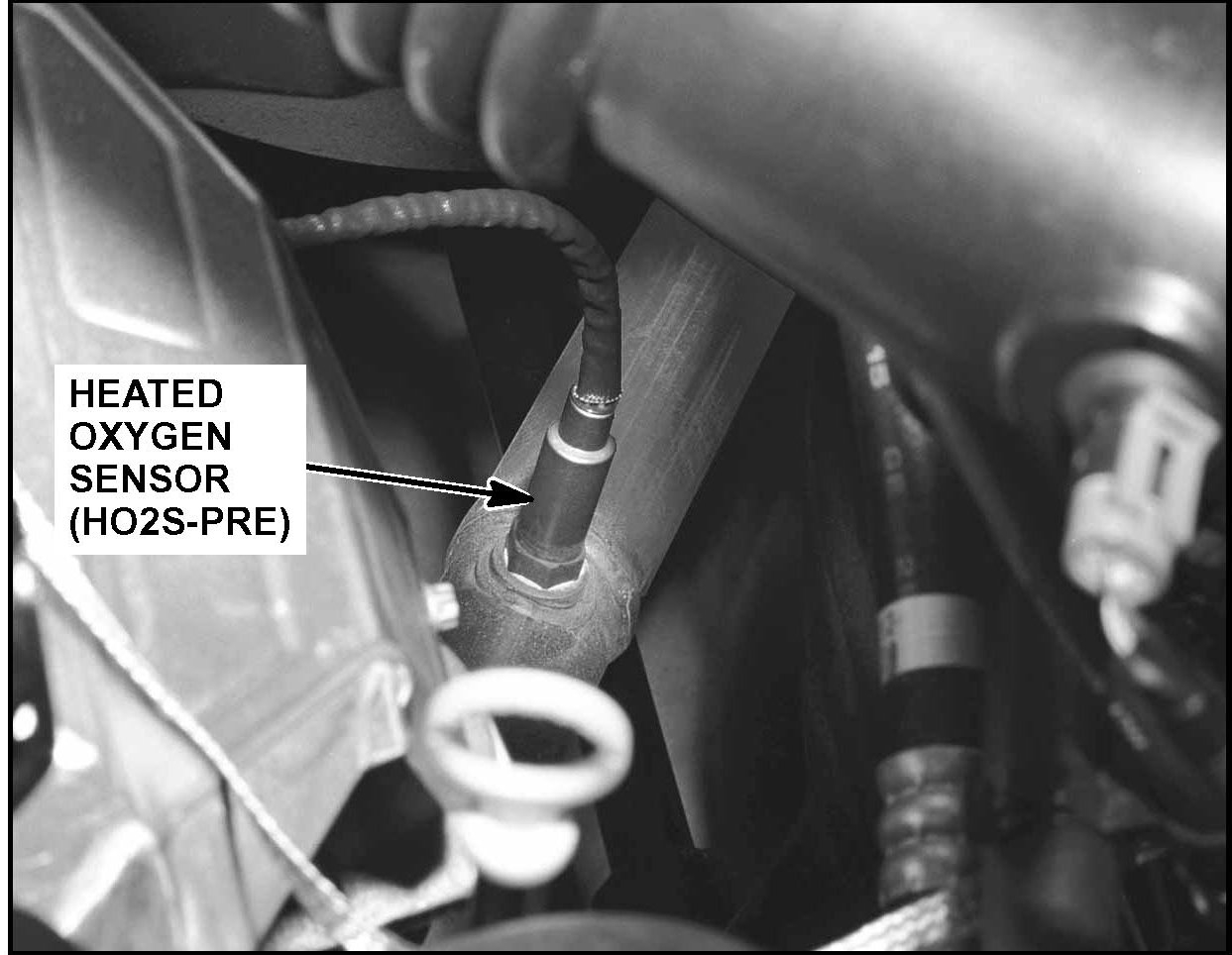

Upstream O2 Sensor

The upstream O2 sensor is located in the exhaust manifold or exhaust pipe, before the catalytic converter. This sensor measures the oxygen content in the exhaust gases before they enter the catalytic converter, and it provides the ECU with information about the air-fuel ratio in the engine.

Downstream O2 Sensor

The downstream O2 sensor is located in the exhaust pipe, after the catalytic converter. This sensor measures the oxygen content in the exhaust gases after they have passed through the catalytic converter, and it provides the ECU with information about the efficiency of the catalytic converter.

The placement of O2 sensors in a vehicle is influenced by several factors, including the type of engine, the emission control system, and the specific design of the vehicle. The ECU uses the information from the O2 sensors to adjust the air-fuel ratio and ensure that the engine is running efficiently and meeting emission standards.

Sensor Types

Oxygen sensors, also known as O2 sensors, are essential components in modern vehicles. They play a crucial role in optimizing engine performance and reducing emissions by measuring the amount of oxygen in the exhaust gases.

There are several types of O2 sensors used in vehicles, each with its own unique characteristics and advantages. The two main types are heated and unheated O2 sensors.

Heated O2 Sensors

- Heated O2 sensors are equipped with a heating element that quickly brings the sensor to its optimal operating temperature, typically around 300 degrees Celsius (572 degrees Fahrenheit).

- This rapid heating allows the sensor to provide accurate readings even during cold engine starts or when the engine is running at low temperatures.

- Heated O2 sensors are more expensive than unheated sensors but offer faster response times and improved accuracy.

Unheated O2 Sensors

- Unheated O2 sensors do not have a heating element and rely on the heat from the exhaust gases to reach their operating temperature.

- They are less expensive than heated sensors but have slower response times and may not be as accurate at low temperatures.

- Unheated O2 sensors are commonly used in older vehicles or in applications where cost is a primary concern.

Sensor Function: O2 Sensor Location

Oxygen sensors play a crucial role in the exhaust system by monitoring the oxygen levels in the exhaust gas. This information is vital for the engine control module (ECM) to precisely control the air-fuel ratio, ensuring optimal engine performance and minimizing emissions.

Measuring Oxygen Levels

O2 sensors employ a unique electrochemical process to measure oxygen levels. They consist of a solid electrolyte material sandwiched between two electrodes: a reference electrode and a sensing electrode. When the sensor is exposed to exhaust gas, oxygen molecules react with the sensing electrode, generating an electrical signal proportional to the oxygen concentration.

Controlling Air-Fuel Ratios

The ECM uses the O2 sensor signal to adjust the air-fuel ratio, ensuring it remains within a narrow range. When the exhaust gas contains excess oxygen (lean condition), the ECM reduces the fuel injection rate, causing the mixture to become richer.

Conversely, if the exhaust gas has low oxygen levels (rich condition), the ECM increases fuel injection, resulting in a leaner mixture.

Sensor Replacement

Replacing an O2 sensor is a relatively straightforward process that can be completed in under an hour with the right tools and materials. Before beginning, ensure the vehicle is parked on a level surface, the engine is turned off, and the parking brake is engaged.

Safety glasses and gloves are recommended for protection.

Tools and Materials, O2 sensor location

To replace an O2 sensor, you will need the following tools and materials:

- New O2 sensor

- Socket wrench or combination wrench

- Oxygen sensor socket (optional but recommended)

- Anti-seize compound

- Penetrating oil (optional)

- Torque wrench (optional)

Sensor Troubleshooting

Identifying and addressing faulty oxygen sensors is crucial for maintaining optimal engine performance and fuel efficiency. Here’s a comprehensive guide to troubleshooting O2 sensor issues:

Common symptoms of a faulty O2 sensor include:

- Check Engine Light (CEL) illumination

- Rough idling

- Poor fuel economy

- Hesitation or stalling during acceleration

- Increased exhaust emissions

Diagnosing a Faulty O2 Sensor

Diagnosing a faulty O2 sensor involves several steps:

- Visual Inspection:Examine the sensor for any physical damage, such as loose connections, frayed wires, or corrosion.

- Code Reading:Use an OBD-II scanner to retrieve any stored diagnostic trouble codes (DTCs) related to the O2 sensor.

- Data Monitoring:Observe the live data stream from the O2 sensor using a scan tool. Look for erratic voltage readings or a slow response time.

- Multimeter Testing:Disconnect the sensor and use a multimeter to measure its resistance and voltage output. Compare the readings to the manufacturer’s specifications.

Troubleshooting Tips

Resolving O2 sensor issues often involves:

- Replacing the faulty sensor with a new one

- Inspecting and repairing any damaged wiring or connectors

- Checking for exhaust leaks or other issues that may affect the sensor’s readings

- Resetting the engine control module (ECM) to clear any stored fault codes

By following these troubleshooting steps, you can effectively diagnose and resolve O2 sensor issues, ensuring optimal engine performance and fuel efficiency.

Last Recap

In conclusion, the O2 sensor’s placement is a carefully orchestrated decision, influenced by a multitude of factors. By understanding its typical locations and the reasons behind them, we gain valuable insights into the intricate workings of our vehicles. Whether you’re a seasoned mechanic or an automotive enthusiast, this knowledge empowers you to diagnose and resolve O2 sensor issues with greater confidence, ensuring your vehicle continues to purr like a well-tuned symphony.

FAQ Compilation

Where is the O2 sensor typically located in a car?

Typically, you’ll find the O2 sensor in the exhaust system, either upstream or downstream of the catalytic converter.

Why are there different locations for O2 sensors in different vehicles?

The placement of the O2 sensor depends on factors such as engine design, exhaust system layout, and emission control requirements.