P0336 crankshaft position sensor location – Kickstart your engine’s health journey with our guide to the P0336 Crankshaft Position Sensor. Discover its hidden abode, learn to spot sensor woes, and master the art of replacement. It’s time to empower your engine with the precision it deserves!

Delve into the depths of your engine bay, where the crankshaft position sensor orchestrates the dance of pistons and valves. This guardian of timing ensures your engine’s symphony stays in perfect harmony. But when it falters, the rhythm falters too, leaving you with a P0336 code and a less-than-stellar engine performance.

Crankshaft Position Sensor: P0336 Crankshaft Position Sensor Location

A crankshaft position sensor is a vital component in the electronic engine management system of a vehicle. Its primary function is to monitor the crankshaft’s rotational position and speed, providing crucial information to the engine control unit (ECU) for various engine management tasks.

The crankshaft position sensor is typically located in close proximity to the crankshaft, either on the front or rear of the engine block. In inline engines, the sensor is usually mounted near the flywheel or timing belt pulley. In V-type engines, the sensor is often located on the side of the engine block, near the crankshaft pulley or camshaft.

Location and Functionality

The location of the crankshaft position sensor affects its functionality in several ways:

- Accuracy:The closer the sensor is to the crankshaft, the more accurate its readings will be. This is because the sensor can detect the crankshaft’s position and speed with greater precision when it is in close proximity.

- Durability:Sensors located away from the crankshaft may be exposed to harsh conditions, such as heat and vibration. This can affect their durability and lifespan.

- Accessibility:Sensors located in easily accessible areas are easier to inspect, maintain, and replace if necessary.

Identifying the Crankshaft Position Sensor

Locating the crankshaft position sensor in an engine bay is crucial for troubleshooting and replacement. Several methods can assist in identifying the sensor’s position.

One common approach is to refer to the vehicle’s service manual or consult online resources that provide specific information for the particular engine type. These resources often include diagrams or illustrations indicating the sensor’s location.

Visual Inspection

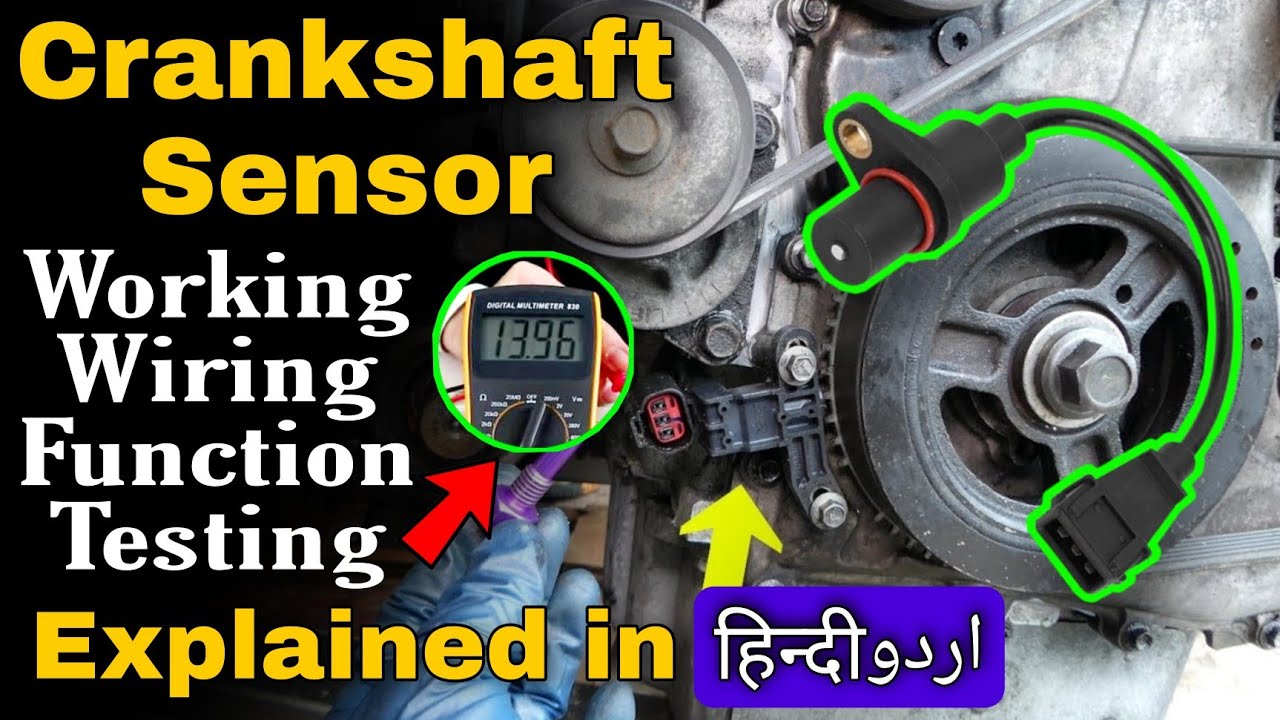

Visually inspecting the engine bay can also aid in locating the crankshaft position sensor. The sensor is typically a small, cylindrical device with a connector attached to one end. It is often mounted on or near the engine block, close to the crankshaft.

Diagnostic Tools

Diagnostic tools, such as an OBD-II scanner or a multimeter, can also be used to identify the crankshaft position sensor. By connecting the scanner to the vehicle’s diagnostic port, it is possible to retrieve trouble codes related to the sensor.

A multimeter can be used to test the sensor’s electrical continuity and resistance.

Common Sensor Locations

| Engine Type | Common Location |

|---|---|

| Inline Engines | At the rear of the engine block, near the flywheel |

| V-Type Engines | Between the cylinder banks, near the crankshaft |

| Diesel Engines | Mounted on the timing gear housing or the injection pump |

Troubleshooting and Replacement Procedures

The crankshaft position sensor (CPS) plays a critical role in engine performance. A faulty CPS can lead to a range of issues, including engine stalling, rough idling, and decreased fuel efficiency. Understanding the symptoms and causes of a faulty CPS is essential for timely diagnosis and repair.

Symptoms of a Faulty Crankshaft Position Sensor

- Engine stalling or difficulty starting

- Rough idling or engine misfiring

- Reduced engine power or fuel efficiency

- Illuminated check engine light

Causes of a Faulty Crankshaft Position Sensor

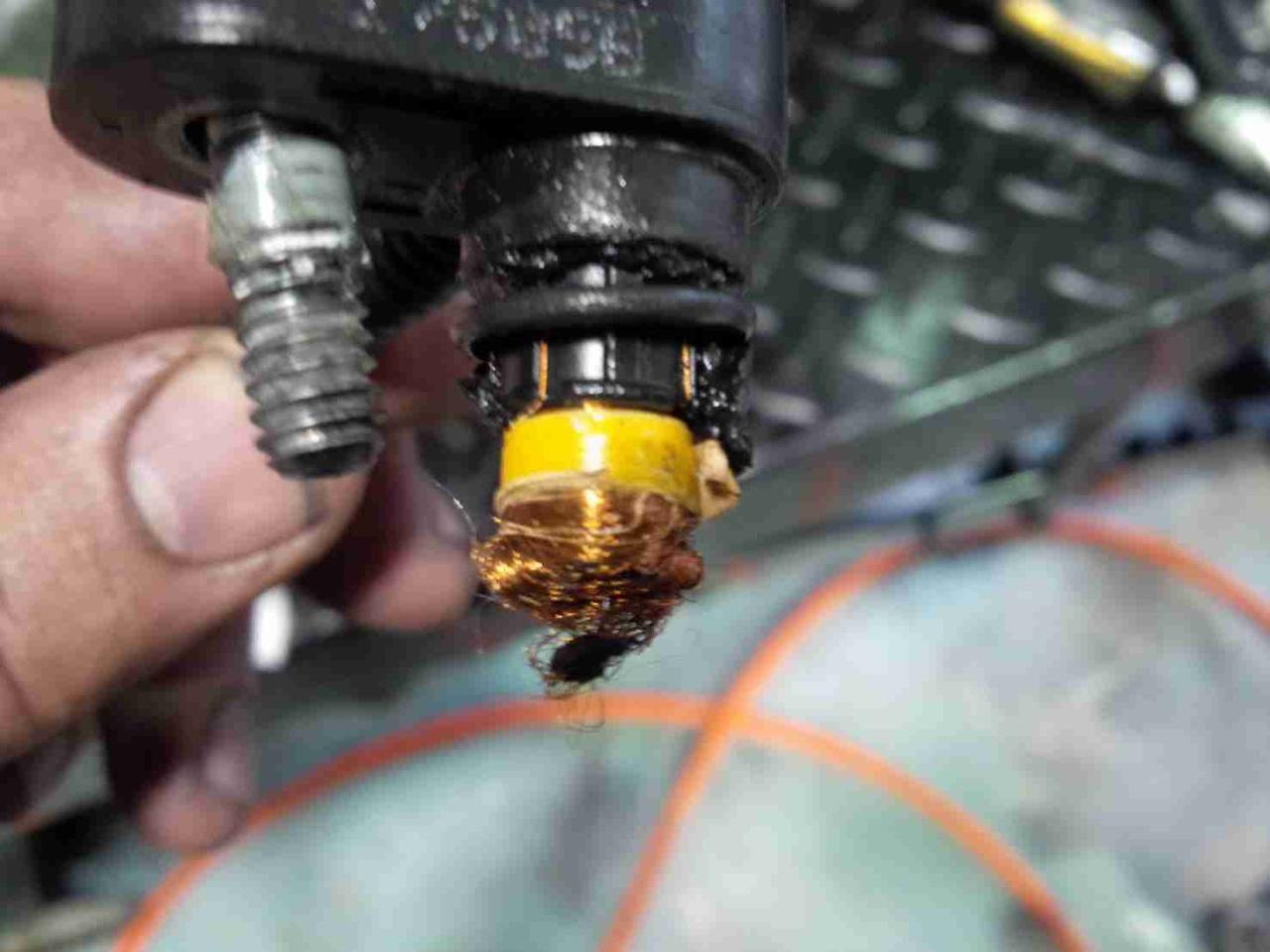

- Physical damage to the sensor or its wiring

- Electrical shorts or open circuits

- Sensor misalignment

- Engine vibration or movement

Replacement Procedures

Replacing a faulty CPS requires careful attention to safety and specific steps for different engine types. Here’s a step-by-step procedure for replacing the sensor:

- Safety Precautions:Disconnect the negative battery terminal before starting any work.

- Locate the CPS:The CPS is typically located near the crankshaft or flywheel, attached to the engine block.

- Disconnect the Electrical Connector:Unplug the electrical connector from the CPS.

- Remove the Mounting Bolts:Unscrew the mounting bolts holding the CPS in place.

- Remove the Faulty Sensor:Carefully pull the faulty CPS out of its mounting hole.

- Install the New Sensor:Insert the new CPS into the mounting hole and secure it with the mounting bolts.

- Reconnect the Electrical Connector:Plug the electrical connector back into the CPS.

- Reconnect the Battery:Reconnect the negative battery terminal.

Replacement Procedures for Different Engine Types

The specific replacement procedure for the CPS may vary depending on the engine type. Here’s a table comparing the procedures for different engine types:

| Engine Type | Replacement Procedure |

|---|---|

| Inline Engine |

|

| V-Engine |

|

| Diesel Engine |

|

Sensor Specifications and Compatibility

Crankshaft position sensors (CPS) have specific technical specifications that determine their functionality and compatibility with different engine models. Understanding these specifications is crucial for proper sensor selection and replacement.

The following table summarizes the key specifications of CPSs:

| Specification | Description |

|---|---|

| Voltage Range | The range of voltage that the sensor can operate within, typically between 5 and 12 volts. |

| Frequency | The number of pulses generated by the sensor per second, which corresponds to the engine speed. |

| Pulse Width | The duration of each pulse generated by the sensor, which can vary depending on the engine’s operating conditions. |

It is essential to ensure that the replacement CPS is compatible with the specific engine model. Incompatible sensors may not provide accurate signals or may even damage the engine. Factors to consider when selecting a replacement sensor include:

- Engine model and year

- Sensor type (e.g., inductive, Hall effect)

- Connector type and wiring harness compatibility

- Manufacturer’s specifications and recommendations

Advanced Diagnostics and Sensor Monitoring

Advanced diagnostic tools offer a comprehensive approach to analyzing crankshaft position sensor performance. These tools provide real-time data and in-depth analysis, allowing technicians to pinpoint sensor issues accurately.

Diagnostic Parameters

Advanced diagnostics monitor various parameters, including:

-

-*Sensor signal waveform

Assesses the shape, amplitude, and frequency of the sensor’s output signal.

-*Timing

Measures the time interval between the sensor’s signal and other engine events, such as spark ignition or fuel injection.

-*Amplitude

Determines the strength of the sensor’s signal, indicating its sensitivity.

-*Frequency

Measures the rate at which the sensor’s signal oscillates, providing information about engine speed.

Diagnostic Tools

-

-*Oscilloscopes

Capture and display the sensor’s waveform, enabling visual analysis of its characteristics.

-*Scan tools

Provide live data, diagnostic trouble codes, and guided tests for the sensor.

-*Dedicated sensor testers

Specialized devices designed specifically for testing crankshaft position sensors, offering advanced diagnostic capabilities.

Case Studies and Real-World Applications

Crankshaft position sensor malfunctions can have significant impacts on engine performance, leading to a range of issues. This section presents case studies and real-world examples to illustrate these impacts and highlight the importance of proper sensor maintenance.

Sensor Location and Vehicle Operation

The location of the crankshaft position sensor plays a crucial role in its ability to accurately detect engine position. In some vehicles, the sensor is mounted on the engine block, while in others, it is located on the transmission bell housing.

The specific location depends on the vehicle’s design and the type of sensor used.

When the sensor is not properly positioned, it may not be able to accurately detect the crankshaft’s position, leading to incorrect timing of the engine’s ignition and fuel injection systems. This can result in reduced engine power, increased fuel consumption, and even engine stalling.

Importance of Proper Sensor Maintenance, P0336 crankshaft position sensor location

Regular maintenance of the crankshaft position sensor is essential to ensure its proper functioning and prevent engine problems. This includes checking the sensor’s electrical connections, inspecting the sensor for damage, and cleaning any debris that may have accumulated around it.

Neglecting sensor maintenance can lead to a range of issues, including:

- Intermittent engine performance problems

- Difficulty starting the engine

- Increased emissions

- Reduced fuel efficiency

- Engine damage in severe cases

Last Point

Mastering the P0336 Crankshaft Position Sensor is your key to a well-tuned engine. By understanding its location, troubleshooting its issues, and replacing it with precision, you become the conductor of your engine’s symphony. Remember, a healthy sensor equals a happy engine, so embrace this knowledge and keep your ride humming along.

Common Queries

Where can I find the crankshaft position sensor?

Its location varies depending on the engine type. Generally, you’ll find it near the crankshaft, flywheel, or timing belt.

What are the symptoms of a faulty crankshaft position sensor?

Engine misfires, rough idling, stalling, and reduced power are common signs.

Can I replace the crankshaft position sensor myself?

Yes, but it requires some mechanical knowledge and tools. Refer to a repair manual for specific instructions.