Universal pig-tail brake controller wiring harness – Step into the world of universal pigtail brake controller wiring harnesses, where safety meets performance. Discover the intricacies of this essential component and unlock the secrets to seamless braking experiences.

From understanding its purpose and compatibility to mastering installation techniques, this guide will empower you with the knowledge to harness the full potential of your brake controller wiring harness.

Universal Pigtail Brake Controller Wiring Harness Overview

A universal pigtail brake controller wiring harness is a device designed to facilitate the installation of a brake controller in a vehicle. It simplifies the process by providing a standardized set of connections that are compatible with most brake controllers and vehicles.

Types of Wiring Harnesses, Universal pig-tail brake controller wiring harness

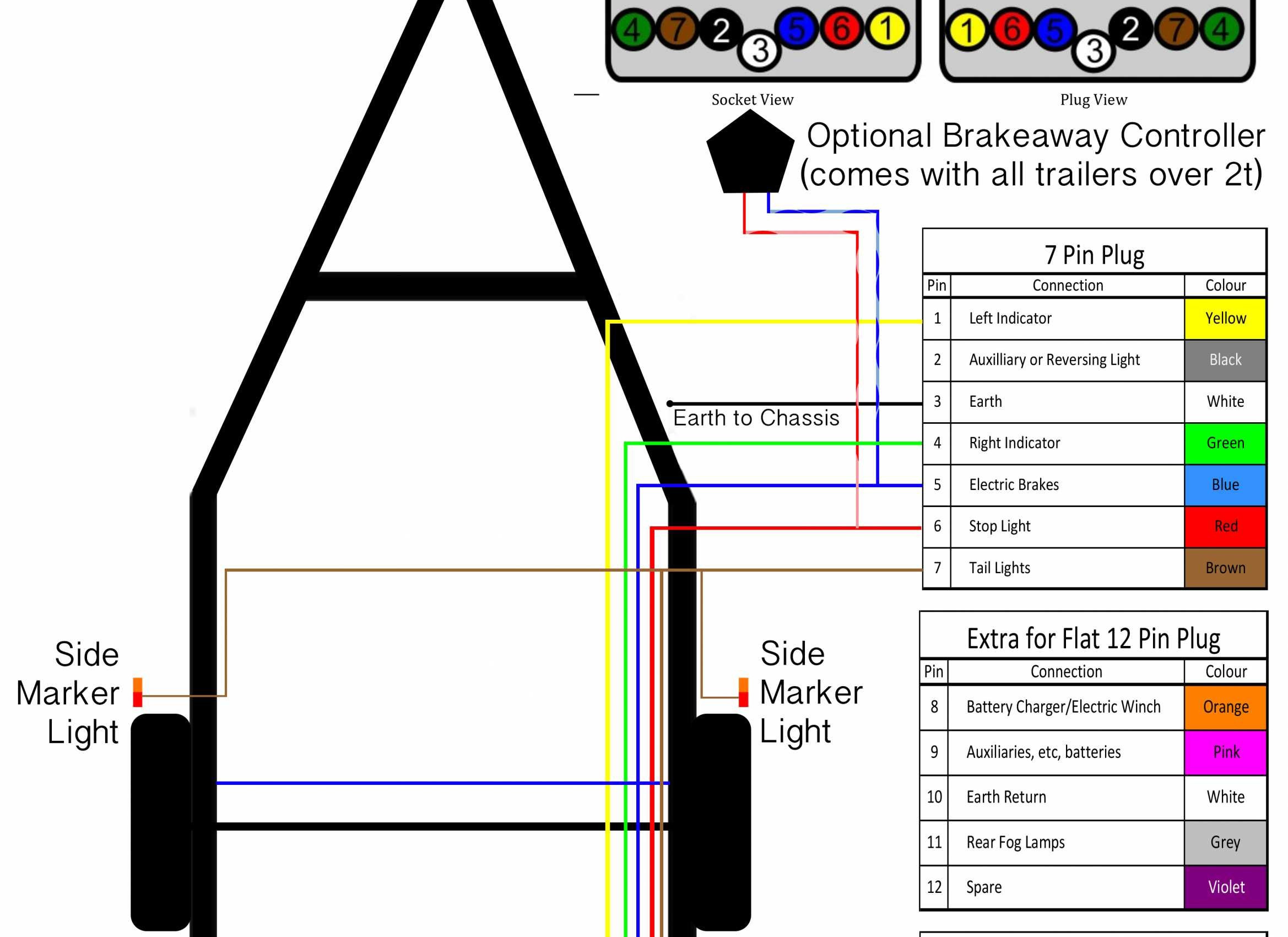

Universal pigtail brake controller wiring harnesses come in various types, each designed to accommodate different brake controllers and vehicle configurations. The primary distinction lies in the connector types and the number of pins available for connections.

Components and Connections

A typical universal pigtail brake controller wiring harness consists of the following components:

Pigtail connector

Plugs into the brake controller.

Vehicle-specific connector

Connects to the vehicle’s electrical system.

Power wire

Supplies power to the brake controller.

Ground wire

Provides a grounding path.

Brake signal wire

Transmits the brake signal from the vehicle to the brake controller.

Output wire

Sends the controlled brake signal to the electric brakes.The diagram below illustrates the typical connections of a universal pigtail brake controller wiring harness:[Insert wiring harness diagram here]

Installation Considerations

Proper installation of a wiring harness is crucial for optimal brake controller performance and safety. Follow these steps to ensure a successful installation:

Wire Routing

Plan the wire routing carefully to avoid interference with other vehicle components. Secure the wires using zip ties or wire loom to prevent damage or shorts.

Splicing

When splicing wires, use heat shrink connectors or solder and electrical tape to create a secure and watertight connection. Test the connections before proceeding.

Grounding

Establish a solid ground connection to the vehicle’s chassis. This ensures proper electrical flow and prevents potential electrical issues.

Safety Precautions

Always disconnect the vehicle’s battery before working on the electrical system. Use proper tools and wear safety glasses.

Troubleshooting Tips

If the brake controller is not functioning properly, check the following:

- Secure connections and splices

- Proper grounding

- Brake pedal switch adjustment

- Trailer wiring and connections

Compatibility and Troubleshooting: Universal Pig-tail Brake Controller Wiring Harness

Ensuring compatibility between your wiring harness, brake controller, and vehicle is crucial for optimal performance. Before installation, verify compatibility using the following steps:

- Check Brake Controller Compatibility:Consult the brake controller manufacturer’s documentation to determine if your harness is compatible with the specific brake controller model you intend to use.

- Verify Vehicle Compatibility:Determine if the harness is designed to work with your vehicle’s electrical system. Refer to the harness manufacturer’s specifications or contact them for assistance.

Common Troubleshooting Issues

Wiring harnesses can encounter various issues. Here are some common problems and troubleshooting tips:

- Electrical Shorts:Inspect the harness for any exposed or damaged wires. Disconnect the harness and use a multimeter to check for continuity. Repair or replace damaged wires as needed.

- Loose Connections:Ensure all connections are secure. Check the tightness of wire nuts, terminals, and connectors. If necessary, tighten or replace loose connections.

- Ground Faults:Verify that the harness is properly grounded. Check the ground connection to the vehicle’s chassis and ensure it is clean and tight. If necessary, clean or replace the ground connection.

Features and Benefits

Universal pigtail brake controller wiring harnesses offer numerous advantages that enhance the performance and safety of towing systems.

By providing a standardized connection between the brake controller and the vehicle’s electrical system, these harnesses simplify installation and ensure reliable operation. Here are some key features and benefits to consider:

Wire Gauge and Length

- Universal wiring harnesses come in various wire gauges and lengths, allowing you to choose the most suitable option for your specific towing needs.

- Heavier wire gauges (e.g., 12-gauge or 14-gauge) minimize voltage drop and ensure efficient power transfer, particularly for larger trailers with demanding braking systems.

- Selecting the appropriate wire length is crucial to avoid excessive slack or insufficient reach, ensuring a clean and functional installation.

Ease of Installation

- Universal wiring harnesses are designed to facilitate quick and straightforward installation, even for novice users.

- Pre-terminated wires and color-coded connections simplify the process, minimizing the risk of incorrect wiring.

- Detailed instructions and support materials are often provided, ensuring a hassle-free installation experience.

Enhanced Braking Performance and Safety

- Properly installed wiring harnesses ensure a reliable connection between the brake controller and the vehicle’s braking system.

- This ensures accurate and timely application of trailer brakes, significantly improving braking performance and reducing stopping distances.

- Enhanced braking control not only protects the vehicle and trailer but also increases overall safety on the road.

Maintenance and Inspection

Regular maintenance and inspection of your universal pigtail brake controller wiring harness are crucial for ensuring its longevity and reliable performance. Neglecting proper care can lead to compromised functionality, safety hazards, and costly repairs.

To maintain the integrity of your wiring harness, it’s essential to conduct periodic inspections to detect any signs of damage or corrosion. This proactive approach allows you to address potential issues early on, preventing them from escalating into major problems.

Visual Inspection

Thoroughly inspect the wires, connections, and terminals for any visible damage, such as cuts, abrasions, or loose connections. Check for signs of corrosion, which can manifest as a greenish or whitish buildup on the metal surfaces. Corrosion can weaken the connections and impair the electrical flow, leading to intermittent or complete failure of the brake controller.

Electrical Testing

Use a multimeter to test the continuity of the wires and the integrity of the connections. Ensure that the wires are properly crimped or soldered and that the connections are secure. Any breaks or faults in the electrical circuit can compromise the functionality of the brake controller.

Preventive Measures

To extend the lifespan of your wiring harness and ensure its reliable performance, consider the following preventive measures:

- Securely mount the wiring harness away from heat sources, sharp edges, and potential sources of damage.

- Use protective sleeves or conduits to safeguard the wires from abrasion and moisture.

- Apply dielectric grease to the connections to prevent corrosion and improve electrical conductivity.

- Avoid overtightening the connections, as this can damage the terminals.

By adhering to these maintenance and inspection practices, you can ensure the longevity and reliable performance of your universal pigtail brake controller wiring harness, enhancing the safety and functionality of your towing system.

Concluding Remarks

In the realm of braking, the universal pigtail brake controller wiring harness stands as a beacon of safety and efficiency. Embrace its versatility and enhance your driving experience with confidence. Remember, proper installation and maintenance are key to unlocking the full potential of this indispensable component.

FAQ Explained

Q: What is the purpose of a universal pigtail brake controller wiring harness?

A: It provides a standardized connection between the brake controller and the vehicle’s electrical system, ensuring compatibility and optimal braking performance.

Q: How do I determine compatibility between the wiring harness and my vehicle and brake controller?

A: Refer to the compatibility table or consult the manufacturer’s specifications to ensure seamless integration.

Q: What are some common troubleshooting issues related to wiring harnesses?

A: Loose connections, electrical shorts, and ground faults can disrupt functionality. Inspect wires, connections, and terminals regularly for any damage or corrosion.